Why Understanding the Plastic Moulding Process is Essential for Manufacturers

Understanding the plastic moulding process is crucial for manufacturers who aim to optimize production efficiency and ensure product quality. As noted by industry expert Dr. Emily Chen, a leading figure in polymer engineering, "Mastering the plastic moulding process not only enhances the creativity of design but also significantly reduces waste and costs." This insight underscores the importance of comprehensively grasping the intricacies of plastic moulding for those in the manufacturing sector.

The plastic moulding process encompasses various methods such as injection, blow, and compression moulding, each offering unique advantages tailored to different production needs. By familiarizing themselves with these techniques, manufacturers can make informed decisions that lead to better resource management and innovative solutions. Furthermore, understanding this process allows businesses to respond effectively to market demands and adapt to the rapid changes in consumer preferences.

As the manufacturing landscape evolves, embracing advances in the plastic moulding process is more essential than ever. This knowledge not only drives operational efficiency but also opens new avenues for innovation and sustainability in product development, positioning manufacturers to thrive in a competitive global market.

Overview of the Plastic Moulding Process and Its Importance

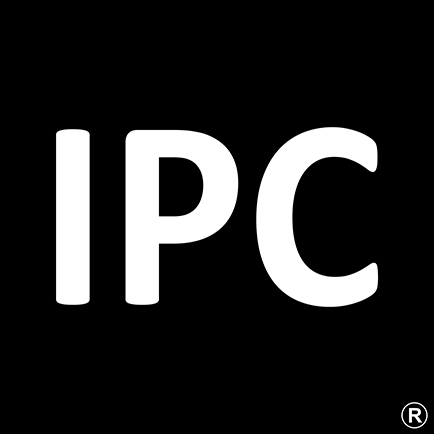

The plastic moulding process is a critical component in the manufacturing industry, serving as the backbone for producing a myriad of products ranging from consumer goods to automotive parts. The process typically involves shaping molten plastic into a specific form using a mould, which is cooled to solidify the material. According to a report by the International Plastics Association, the plastic moulding market is projected to reach $450 billion by 2025, underscoring the importance of efficient moulding techniques for manufacturers aiming to remain competitive in a bustling market.

Understanding the intricacies of plastic moulding is essential not only for enhancing product quality but also for optimizing production efficiency. For instance, adopting advanced injection moulding techniques can reduce cycle times by as much as 20%, translating into substantial cost savings for manufacturers. Additionally, a survey conducted by the Society of Plastics Engineers revealed that 90% of professionals believe that regular training and updates on moulding technologies significantly improve product performance and reduce waste. Manufacturers that invest in mastering the plastic moulding process position themselves not just to meet demand, but to innovate within their respective sectors, ensuring sustainable growth and adaptation to evolving market trends.

Key Types of Plastic Moulding Techniques for Manufacturers

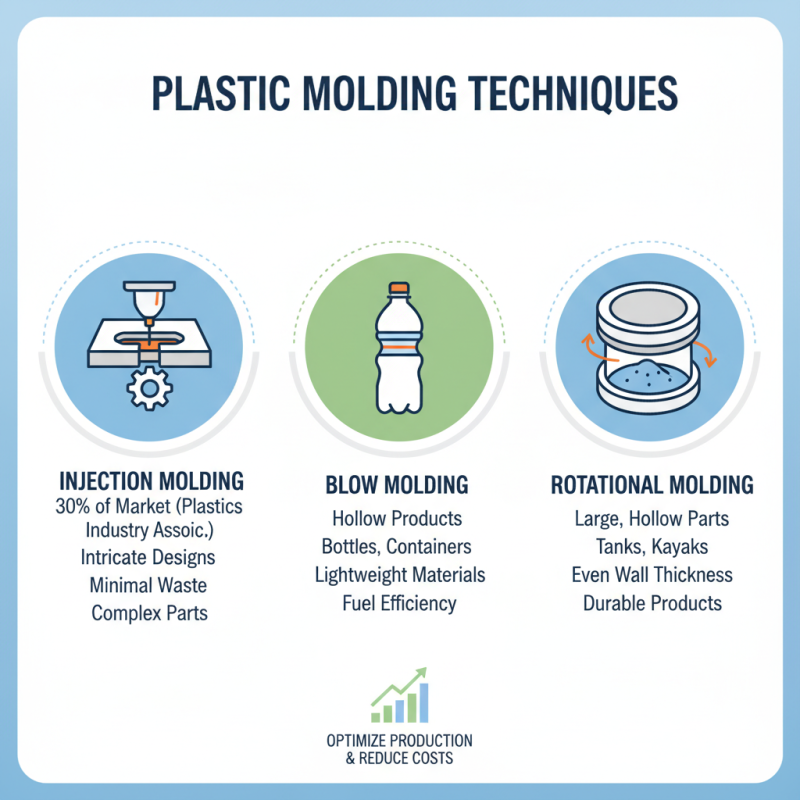

Understanding the various plastic moulding techniques is essential for manufacturers aiming to optimize production efficiency and reduce costs. Among the most prevalent methods are injection moulding, blow moulding, and rotational moulding. According to the Plastics Industry Association, injection moulding accounts for approximately 30% of the entire plastics processing market. This process is favored for its high production speed and ability to create intricate designs with minimal material waste. Conversely, blow moulding is primarily used for creating hollow plastic products, such as bottles, and is gaining traction as industries focus on lightweight materials to enhance fuel efficiency in transportation.

When selecting a moulding technique, manufacturers should consider the product specifications and production volumes. Injection moulding is suitable for high-volume production, while blow moulding is ideal for less complex designs. Rotational moulding, often used for larger items like tanks and crates, offers excellent flexibility for custom shapes. A report from Research and Markets indicates that the global rotational moulding market is expected to grow significantly, driven by the demand for lightweight and durable containers.

Tips: Always conduct a cost-benefit analysis before choosing a moulding process. Consider the upfront tooling costs and the anticipated production run to identify the most cost-effective option. Additionally, staying updated with technological advancements in moulding techniques can provide competitive advantages in terms of quality and production timelines.

Factors Influencing the Plastic Moulding Process Efficiency

The efficiency of the plastic moulding process is influenced by several critical factors that manufacturers must consider to optimize production. One of the primary factors is the material selection, which involves choosing the right type of plastic that has the appropriate properties for the desired application. The characteristics of the plastic, such as its viscosity and thermal stability, can significantly impact the flow and cooling behavior during the moulding process. Additionally, the quality and consistency of the raw materials can affect the final product's integrity and performance.

Another vital factor influencing efficiency is the design of the mould itself. A well-engineered mould can enhance the flow of materials, reduce cycle times, and minimize defects. Features such as venting, cooling channels, and the overall geometry play a crucial role in achieving optimal results. Moreover, the parameters set during the moulding process, including temperature, pressure, and injection speed, must be precisely controlled to ensure quality and reduce waste. By understanding and addressing these factors, manufacturers can improve the efficiency of the plastic moulding process, leading to better productivity and cost savings.

Why Understanding the Plastic Moulding Process is Essential for Manufacturers - Factors Influencing the Plastic Moulding Process Efficiency

| Factor | Description | Impact on Efficiency | Average Efficiency (%) |

|---|---|---|---|

| Material Selection | Choosing the right plastic material for the moulding process affects durability and performance. | High-quality materials lead to fewer defects and reduced waste. | 85 |

| Process Temperature | Temperature plays a critical role in the melting and flow of plastics during moulding. | Optimal temperatures improve cycle times and product quality. | 90 |

| Mould Design | Efficient mould design aids material flow and reduces cooling time. | Well-designed moulds significantly decrease production time. | 80 |

| Cooling Time | Time required for the plastic to cool and solidify inside the mould. | Longer cooling times can delay production but are necessary for quality. | 70 |

| Operator Skill Level | The experience and expertise of the operators managing the moulding process. | Skilled operators can quickly troubleshoot issues and optimize processes. | 75 |

Common Challenges in Plastic Moulding and Their Solutions

The plastic moulding process is rife with challenges that manufacturers need to navigate effectively to ensure high-quality production. Common pitfalls include material wastage, inconsistent product quality, and machine malfunctions. Each of these issues can lead to increased costs and delays in production schedules. Understanding the root causes is crucial for manufacturers to devise effective solutions.

One prevalent challenge is achieving consistent product quality. Fluctuations in temperature, pressure, and material quality can all impact the outcome. To combat this, manufacturers should implement rigorous quality control procedures and invest in precise moulding equipment. Regular maintenance of machinery is also vital to prevent breakdowns that can halt production.

**Tips:** Regularly calibrating machines and conducting quality checks at different stages of the moulding process can help identify potential issues early on. Additionally, training staff to recognize quality issues can foster a culture of diligence in production practices.

Another challenge is material wastage, which can occur due to inefficient designs or improper use of materials. Employing simulation software prior to actual production can help identify the most efficient method and material usage. This proactive approach not only reduces waste but also enhances overall productivity.

**Tips:** Consider recycling excess material whenever possible and utilize predictive maintenance strategies to keep equipment running smoothly and efficiently.

Future Trends in Plastic Moulding Technology and Sustainability

The landscape of plastic moulding technology is undergoing rapid transformation as manufacturers increasingly prioritize sustainability. Recent studies, such as a report by Smithers Pira, indicate that the global market for sustainable plastic solutions is projected to reach $450 billion by 2027, showcasing a significant shift towards eco-friendly practices. Innovations in bioplastics and recycled materials are leading the charge, enabling manufacturers to reduce their carbon footprint while meeting consumer demand for sustainable products. Adopting these technologies not only aids the environment but also aligns with the growing regulatory pressures across the globe.

As manufacturers navigate these emerging trends, it is crucial to implement best practices in plastic moulding processes. Understanding the latest developments in materials, such as biodegradable polymers and enhanced recycling techniques, can provide a competitive advantage. For instance, utilizing techniques like injection moulding with recycled content can yield high-quality products without sacrificing performance.

Tips: Manufacturers should stay updated with industry publications and attend workshops to learn about new moulding technologies and sustainable practices. Additionally, investing in employee training on these innovative techniques can foster a culture of sustainability within the organization. Exploring partnerships with research institutions can also provide insights into cutting-edge developments in the plastic moulding sector.

Plastic Moulding Process Overview: Trends and Sustainability

Related Posts

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

Top 10 Plastic Raw Materials Used in the Manufacturing Industry Today

-

10 Essential Tips for Selecting Rigid PVC Pipe: Maximize Durability and Performance Based on Industry Standards

-

What is PVC Additives and How Do They Enhance Plastic Performance