2025 Top Uses for PVC Plastic You Need to Know About

As we look ahead to 2025, the versatility of PVC plastic continues to play a pivotal role in various industries and applications. Known for its strength, durability, and lightweight characteristics, PVC plastic has established itself as a trusted material in everything from construction to healthcare. This article delves into the top uses of PVC plastic that are revolutionizing everyday products and services.

Whether it's in the realm of innovative packaging solutions or essential building materials, the growing demand for eco-friendly and cost-effective alternatives makes PVC plastic an increasingly popular choice. As we explore the future applications of this remarkable material, we will highlight how PVC plastic is not only transforming traditional practices but also paving the way for more sustainable and efficient solutions across multiple sectors. Join us as we uncover the most significant and impactful uses of PVC plastic that you need to be aware of in the coming years.

Future Trends in PVC Plastic Usage: A Comprehensive Overview

The future of PVC plastic is set to be shaped by a variety of innovative applications driven by environmental considerations and technological advancements. According to a report from Grand View Research, the global PVC market is projected to reach $88.14 billion by 2025, growing at a CAGR of 4.5% from 2019. This growth is influenced by the heightened demand for sustainable building materials, where PVC's durability and recyclability play crucial roles. The construction sector is anticipated to be a significant driver, with PVC increasingly being utilized in energy-efficient windows, roofing membranes, and piping systems designed to reduce water waste.

In addition to construction, the automotive sector is also exploring the benefits of PVC. A study by Markets and Markets indicates that the automotive PVC market is expected to cross $26.5 billion by 2025, driven by the need for lightweight, cost-effective materials that enhance fuel efficiency while maintaining safety standards. Furthermore, advancements in PVC formulations are leading to enhanced performance characteristics, allowing for increased flexibility and heat resistance. These improvements position PVC as a versatile choice for various automotive components, from interior panels to electrical insulation. As sustainability becomes a priority, the emphasis on eco-friendly PVC production methods will also reshape the industry's landscape, ensuring that PVC remains a key player in future applications.

The Role of PVC in Construction: Market Statistics and Innovations

In recent years, PVC plastic has emerged as a cornerstone material in the construction industry, largely due to its versatility, durability, and cost-effectiveness. According to a report from the Allied Market Research, the global PVC market in construction is projected to reach $349 billion by 2025, driven by increasing urbanization and a surge in infrastructure projects. This growth reflects a substantial shift in how PVC is being integrated into structural applications, from plumbing and piping systems to decorative elements in residential and commercial buildings.

Innovations in PVC manufacturing further enhance its role in construction. Techniques such as foaming and the introduction of additives have improved its thermal insulation and fire resistance properties, making it an even more attractive option for builders and architects. The Plastics Industry Association indicates that nearly 70% of all PVC produced is utilized in the construction sector, showcasing its significance as a sustainable alternative to traditional building materials.

As building standards continue to evolve towards sustainability, the demand for PVC, especially in energy-efficient applications, is expected to rise, positioning this material firmly at the forefront of the future construction landscape.

Environmental Concerns: Recycling and Sustainability of PVC Plastic

PVC plastic, or polyvinyl chloride, is a versatile material widely used in construction, healthcare, and consumer goods. However, its environmental impact has raised significant concerns, particularly regarding sustainability and recycling practices. Traditional PVC production involves harmful processes that can release toxic chemicals, and its durability makes it difficult to degrade naturally. This has led to increased scrutiny over its lifecycle and the need for more sustainable practices within the industry.

Recycling efforts for PVC plastic are crucial in mitigating its environmental effects. While PVC is recyclable, the process can be complex due to the presence of additives and other materials within products. To promote effective recycling, it is essential to develop better sorting technologies and raise public awareness about proper disposal methods. Some companies are now focusing on closed-loop systems that allow for the reprocessing of PVC into new products, reducing reliance on virgin materials and conserving resources. Moreover, innovative applications of recycled PVC, such as in the manufacturing of new building materials, can significantly lessen the environmental footprint of this widely-used plastic. As sustainability becomes a priority for consumers and manufacturers alike, the recycling and responsible use of PVC will play a critical role in addressing environmental challenges and fostering a more circular economy.

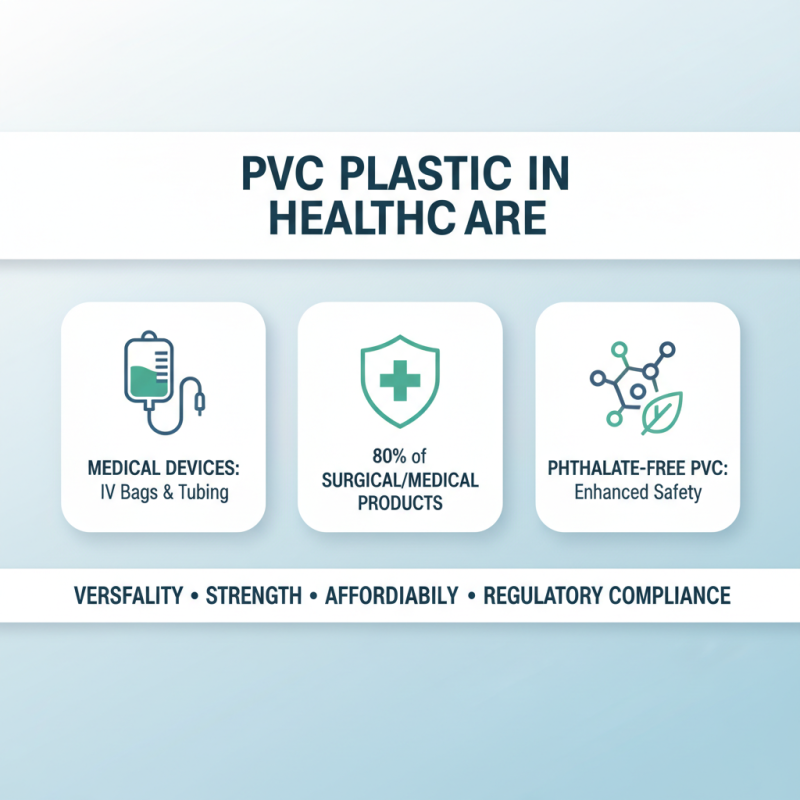

Healthcare Applications: PVC Conversion Rates and Safety Standards

PVC plastic plays a crucial role in the healthcare sector due to its versatility and safety standards. One of the prominent uses of PVC is in the production of medical devices, including intravenous (IV) bags and tubing. According to the Plastics Industry Association, approximately 80% of surgical and medical products utilize PVC, owing to its unmatched strength and relative affordability. Furthermore, advancements in formulation technology have resulted in the development of phthalate-free PVC, which enhances safety without compromising performance. Such innovations align with stringent regulatory standards, ensuring that PVC used in healthcare applications is safe for patients and healthcare workers.

Conversion rates of PVC in the medical field are notably high, with research indicating that over 90% of medical PVC products are recycled or repurposed effectively. The European Union's medical product regulations mandate that materials used in medical devices must pass rigorous safety assessments, which reinforces the trust in PVC's application. Additionally, the integration of additive manufacturing techniques has streamlined the production of customized PVC healthcare products, meeting specific needs while adhering to health and safety regulations. As the healthcare industry continues to evolve, the reliance on PVC remains steadfast, underscoring its significance in providing safe and effective medical solutions.

Consumer Goods: PVC Market Growth and Product Diversification Trends

As the PVC market continues to evolve, the consumer goods sector is witnessing significant growth and diversification. Manufacturers are increasingly recognizing the versatility of PVC, developing a wide range of products that cater to changing consumer preferences. High-quality, flexible materials are being used in everything from packaging to home furnishings, allowing brands to introduce innovative solutions that align with sustainability goals and cost-effectiveness.

Tips: When exploring PVC products, consider opting for those labeled as recycled or recyclable. This not only supports a circular economy but also ensures you make environmentally conscious choices that reduce plastic waste.

In addition to traditional applications, advancements in technology are enabling new uses for PVC. For instance, the construction industry is leveraging PVC for waterproofing solutions and durable flooring options, while the fashion sector is venturing into PVC shoes and accessories that boast both style and practicality. As consumer awareness about sustainability rises, products that highlight eco-friendly practices and materials are becoming increasingly desirable.

Tips: Stay informed about product certifications that indicate environmentally friendly practices. These may include labels such as Green Seal or similar, which can help guide you toward sustainable choices in PVC consumer goods.

Related Posts

-

Why Plastic Granules Are the Key to Sustainable Manufacturing and Recycling

-

Understanding the Impact of Injection Molding Pellets on Sustainable Manufacturing Practices

-

10 Best Rigid PVC Applications You Need to Know in 2023

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

Top 5 Benefits of Injection Tooling for Efficient Manufacturing Process

-

Why Choose PVC Pellets for Injection Molding in Your Manufacturing Process