Top 10 Plastic Raw Materials Used in the Manufacturing Industry Today

In today's rapidly evolving manufacturing landscape, the significance of plastic raw materials cannot be overstated. With applications ranging from automotive parts to packaging solutions, these materials have become essential in meeting the demands of modern production processes. As highlighted by Dr. Emily Chen, a renowned expert in polymer science, "The choice of plastic raw material can dramatically influence not only the efficiency of the manufacturing process but also the sustainability of the final product."

Manufacturers are increasingly recognizing the pivotal role that different types of plastic raw materials play in enhancing product performance while balancing environmental concerns. The versatility of these materials allows for innovation across various industries, making it crucial to stay informed about the top options available. This article delves into the ten most widely used plastic raw materials in manufacturing today, offering insights into their properties, applications, and the reasons behind their popularity.

As we explore these materials, it becomes clear that understanding their characteristics is essential for manufacturers looking to optimize production and achieve their sustainability goals. The journey into the world of plastic raw materials not only showcases their integral role in modern manufacturing but also illuminates the path toward more responsible and innovative practices.

Overview of Plastic Raw Materials in the Manufacturing Industry

In the manufacturing industry, plastic raw materials play a crucial role in producing a wide array of products across various sectors. Plastics are favored for their versatility, lightweight properties, and durability, allowing manufacturers to create items that meet specific performance requirements. Commonly used plastics include polycarbonate, polypropylene, polyethylene, and polystyrene, each with unique attributes suited for different applications. For example, polycarbonate is known for its impact resistance, making it ideal for safety equipment and electrical components, while polypropylene is favored for its chemical resistance and ability to be molded into intricate shapes.

Moreover, the growing emphasis on sustainability has prompted the industry to explore bio-based plastics and recycled materials. These alternatives offer a more environmentally friendly option while maintaining the functional benefits of traditional plastics. As manufacturers aim to reduce their carbon footprint, the integration of these sustainable materials is becoming increasingly prevalent. The ongoing innovations in plastic material science also foster expanded use cases, making it a dynamic area within the manufacturing industry where technology and environmental stewardship converge.

Common Types of Plastic Raw Materials and Their Applications

Plastic raw materials play a crucial role in the manufacturing industry, offering versatility and functionality across various applications. Among the most common types are polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Polyethylene is renowned for its durability and flexibility, making it ideal for packaging materials, containers, and various consumer products. Its resistance to moisture and chemicals also enhances its appeal in the food and beverage industry.

Polypropylene, known for its strength and lightweight characteristics, is often used in automotive components, textiles, and household items. Its ability to withstand high temperatures makes it suitable for applications that require thermal resistance.

On the other hand, PVC is frequently utilized in construction materials, plumbing pipes, and electrical cable insulation due to its excellent durability and resistance to environmental factors. These plastic raw materials not only enhance the performance of finished products but also contribute to the efficiency of manufacturing processes, showcasing the integral role of plastics in modern industrial applications.

Key Properties That Make Plastics Ideal for Manufacturing

Plastics are pivotal in the manufacturing industry, characterized by several key properties that make them an ideal choice for a variety of applications. One of the primary advantages of plastic raw materials is their versatility. Different types of plastics can be engineered to exhibit specific characteristics, such as flexibility, rigidity, or resistance to impact. This adaptability allows manufacturers to tailor materials to meet the exact requirements of their products, whether they need lightweight components for automotive applications or durable casings for electronics.

Another significant property of plastics is their corrosion resistance. Unlike metals, plastics do not rust or degrade when exposed to moisture or harsh chemicals, extending the operational lifespan of products and reducing maintenance costs. Additionally, the lightweight nature of plastics contributes to improved energy efficiency in production and transportation, making it easier for manufacturers to comply with sustainability goals. Moreover, plastics can be molded into intricate shapes and designs, enabling innovative designs that would be challenging to achieve with traditional materials. These properties collectively position plastics as a cornerstone in modern manufacturing.

Environmental Impact of Plastic Raw Materials in Industry

The environmental impact of plastic raw materials in the manufacturing industry is a critical issue that cannot be overlooked. While plastics are integral to many sectors due to their versatility and cost-effectiveness, their production and disposal have significant ecological consequences. The extraction of fossil fuels for plastic manufacturing contributes to greenhouse gas emissions and climate change. Furthermore, the chemical process involved in creating plastic materials often results in the release of hazardous pollutants, which can severely affect air and water quality, threatening both human health and biodiversity.

Additionally, the lifecycle of plastic materials poses challenges upon reaching the end of their useful life. Many plastics are non-biodegradable, leading to accumulation in landfills and oceans. This persistence results in long-term environmental hazards, as wildlife can ingest plastic debris or become entangled in it. Moreover, the microplastics that form from the breakdown of larger items infiltrate ecosystems, entering the food chain and impacting various species. As awareness of these issues grows, industries are increasingly urged to shift towards more sustainable practices, including the use of bioplastics or recycling initiatives to mitigate the detrimental effects on our environment.

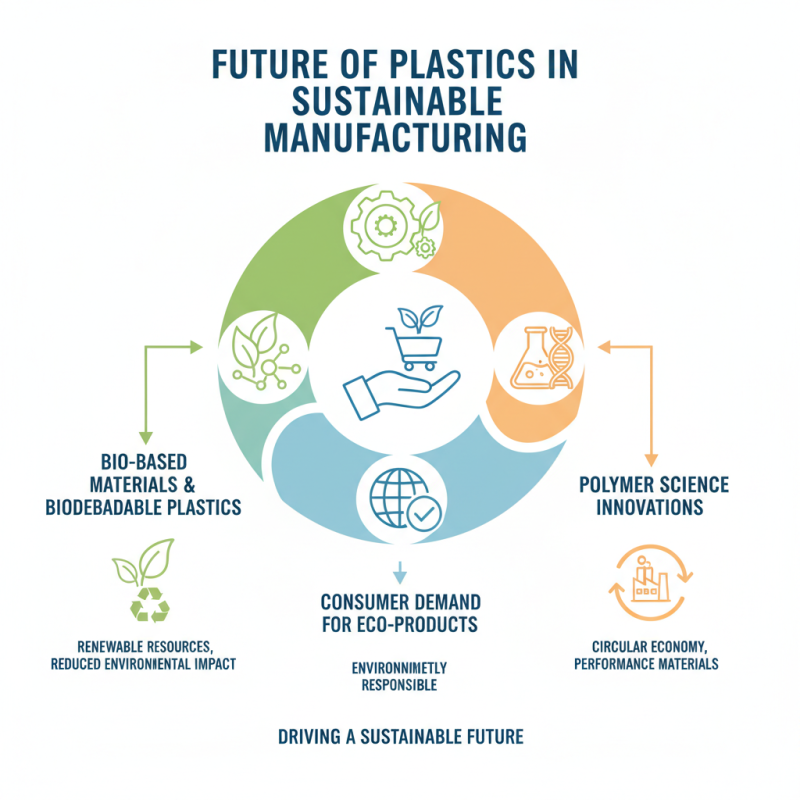

Future Trends in Plastic Raw Materials for Sustainable Manufacturing

The future of plastic raw materials in sustainable manufacturing is poised for significant transformation as industries emphasize eco-friendly practices. A shift towards biodegradable plastics and bio-based materials is gaining momentum, driven by consumer demand for environmentally responsible products. Innovations in polymer science are enabling manufacturers to create alternatives derived from renewable resources, reducing reliance on fossil fuels and minimizing environmental impact. These advancements highlight the potential for developing materials that not only fulfill performance criteria but also contribute to a circular economy.

Additionally, recycling technologies are advancing rapidly, allowing for more efficient processing of post-consumer plastic waste. Enhanced methods such as chemical recycling can break down plastics into their original monomers, facilitating the production of high-quality recycled materials. This type of innovation not only helps in diverting waste from landfills but also promotes resource conservation by incorporating previously used plastics back into the manufacturing cycle. As companies increasingly adopt practices that incorporate recycled content, the landscape of plastic raw materials will evolve, aligning with global sustainability goals while still meeting industrial demands.

Related Posts

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Understanding the Applications and Advantages of PVC Extruded Profiles in Modern Construction

-

10 Essential Tips for Mastering Large Injection Moulding Techniques

-

What is Plastic Raw Material Types and Their Applications

-

What is PVC Additives and How Do They Enhance Plastic Performance