2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

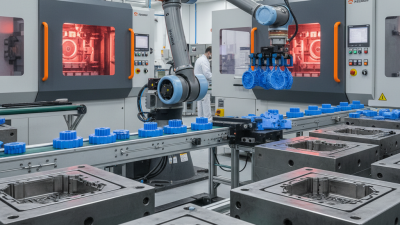

The manufacturing landscape is continuously evolving, driven by advancements in technology and an increasing demand for efficiency. Among the various factors influencing production processes, the choice of materials plays a critical role. Injection molding pellets, a key component in the injection molding process, have seen significant innovation in recent years. According to a report by Mordor Intelligence, the global injection molding market is projected to reach a value of $380 billion by 2025, underscoring the importance of selecting the right pellets to enhance manufacturing efficiency and reduce costs.

As manufacturers seek to optimize their production lines, the selection of the most suitable injection molding pellets is crucial. Factors such as material properties, recycling capabilities, and processing speed can have a profound impact on productivity and product quality. A recent study by Grand View Research indicates that the demand for high-performance plastics is expected to grow at a compound annual growth rate (CAGR) of 6.6% from 2023 to 2030. This growth emphasizes the necessity for manufacturers to stay ahead of the curve in terms of material selection to meet both performance standards and sustainability goals.

In this context, we will explore the top five injection molding pellets expected to dominate the manufacturing sector by 2025. These innovative materials not only promise enhanced efficiency but also cater to the evolving needs of the industry, making them essential for any forward-thinking production strategy.

Future Trends in Injection Molding Pellets: A 2025 Forecast

As we look forward to 2025, the landscape of injection molding pellets is poised for transformative change. Notably, the global market for polybenzimidazole (PBI) is expected to reach $36.16 million, with an impressive growth rate expected to surge to $58.86 million by 2033, reflecting a compound annual growth rate (CAGR) of 6.3%. This highlights the increasing demand for high-performance materials that enhance manufacturing efficiency and product durability.

The metal injection molding sector is also on track for significant expansion. Projections indicate that by 2025, the market will exceed $5.15 billion, with an anticipated CAGR exceeding 9.1%. This growth is largely driven by rising demand in sectors such as firearms manufacturing. As manufacturers embrace innovative technologies and materials, the injection molding industry is set to advance, promising enhanced efficiency and product performance.

Tips: When exploring materials for injection molding, consider the performance characteristics that align with your specific manufacturing needs. Additionally, staying ahead of material trends can help you leverage emerging technologies for better efficiency. Lastly, fostering relationships with suppliers can provide valuable insights into the latest developments in the industry.

Key Features of High-Performance Injection Molding Pellets

When it comes to enhancing manufacturing efficiency in 2025, the choice of

injection molding pellets plays a pivotal role. High-performance pellets are engineered with

specific characteristics that optimize production processes. One key feature is their thermal stability, which allows for consistent processing at elevated temperatures without degradation. This stability not only improves the quality of the final products but also reduces material waste during manufacturing, contributing to a more sustainable operation.

Another vital aspect of these advanced injection molding pellets is their flow properties.

Pellets designed for superior flow can fill complex molds more efficiently, ensuring uniform distribution and minimizing cycle time.

This feature helps manufacturers achieve faster production rates without sacrificing quality. Furthermore, certain high-performance pellets

exhibit enhanced adhesion and compatibility with various additives, allowing for tailored properties and performance that meet diverse application requirements. By focusing on these key features, manufacturers can significantly boost their operational efficiency and maintain a competitive edge in the market.

Comparative Analysis of Top Injection Molding Pellets for Manufacturing

The injection molding industry continues to evolve, with manufacturers increasingly seeking materials that enhance production efficiency. A comparative analysis of the top five injection molding pellets reveals distinct advantages that cater to diverse manufacturing needs. Among these, high-performance polymers stand out due to their excellent strength-to-weight ratio, thermal stability, and ease of processing. These characteristics not only facilitate faster cycle times but also result in reduced energy consumption during production.

Natural fiber composites have also garnered attention, presenting a sustainable alternative that combines strength with lightweight properties. Their incorporation into the injection molding process not only boosts environmental sustainability but also enhances the mechanical properties of the final products. This trend reflects a growing commitment within the industry to innovate and adopt materials that not only improve performance but also align with ecological considerations.

As manufacturers continue to refine their processes and material selections, the competitive landscape of injection molding pellets will play a crucial role in driving operational efficiencies and advancing product quality.

Sustainability and Eco-Friendly Options in Injection Molding Materials

The focus on sustainability in injection molding materials is becoming increasingly significant as industries evolve towards eco-friendliness and reduced environmental impact. Innovations such as polyester-based thermoform-ready packaging are exemplifying how manufacturers can address environmental concerns while maintaining product effectiveness. This approach not only caters to the rising demand for eco-conscious products but also aligns with regulatory standards, particularly in regions like Europe where sustainability is a paramount concern.

In addition to pharmaceutical packaging, sustainable alternatives are emerging in various sectors, including the development of biodegradable plastics. By utilizing materials that break down naturally, manufacturers can minimize their ecological footprint while meeting the growing consumer demand for sustainable products. The introduction of options like environmentally friendly biodegradable plastic chains demonstrates the potential for wide adoption of such materials in manufacturing. As companies increasingly prioritize sustainability, the selection of eco-friendly injection molding pellets will play a crucial role in enhancing manufacturing efficiency and supporting a greener future.

Cost-Effectiveness of Advanced Injection Molding Pellets for Production Efficiency

The evolution of injection molding has led to the development of advanced pellets that not only enhance production efficiency but also provide significant cost-effectiveness. In 2025, manufacturers will benefit from using specialized pellets designed to optimize the molding process, reduce cycle times, and ultimately lower production costs. These advanced materials are formulated to improve the flow characteristics and enable quicker cooling, allowing for greater output with less energy consumption.

Tips: When selecting injection molding pellets, consider the material's thermal stability and compatibility with your existing machinery. This can prevent costly downtimes and improve overall productivity. Additionally, working closely with pellet suppliers to understand their pricing structures and potential bulk order discounts can lead to substantial savings in material costs.

Moreover, the new generation of pellets often comes with enhanced properties such as increased durability or improved chemical resistance. Implementing these innovative materials can lead to superior product quality, reducing the need for post-processing and minimizing waste.

Tips: Regularly evaluate your manufacturing processes for integration opportunities of these advanced pellets. Conducting small-scale tests can help you assess their performance before fully committing to a larger production run, ensuring you make informed decisions that bolster both efficiency and profitability.

Related Posts

-

Understanding the Impact of Injection Molding Pellets on Sustainable Manufacturing Practices

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

Top 5 Benefits of Injection Tooling for Efficient Manufacturing Process

-

2025 Trends in Mold Injection Molding: Innovations and Market Insights