Top 10 Benefits of the Plastic Moulding Process You Need to Know

The plastic moulding process is a revolutionary technique that has transformed the landscape of manufacturing, offering unmatched versatility and efficiency. As industries continue to evolve, understanding the significant advantages of this process becomes crucial for businesses looking to optimize production and reduce costs. The plastic moulding process not only enables the creation of complex shapes and designs but also allows for the mass production of high-quality components, making it an essential method in sectors ranging from automotive to consumer goods.

In this article, we will explore the top ten benefits of the plastic moulding process, highlighting how it can enhance productivity, minimize waste, and improve overall product performance. From its ability to reduce labor costs to its contribution to sustainability efforts, the advantages of this manufacturing technique are profound. Whether you are a manufacturer, an engineer, or simply an enthusiast interested in advanced production methods, gaining insight into the plastic moulding process will equip you with the knowledge needed to leverage its benefits for your projects and innovations. Join us as we delve into the distinct features and applications that make the plastic moulding process a cornerstone of modern manufacturing.

Understanding the Plastic Moulding Process: An Overview

The plastic moulding process is a cornerstone of modern manufacturing, known for its efficiency and versatility. In essence, plastic moulding involves shaping plastic materials into predefined forms using molds. This method encompasses various techniques, including injection moulding, blow moulding, and rotational moulding, each suited for specific applications and types of plastic. According to a report by Mordor Intelligence, the global injection moulding market size is expected to reach USD 364.13 billion by 2027, growing at a CAGR of 5.26%. This growth underscores the widespread reliance on plastic moulding across industries, from automotive to consumer goods.

In addition to its economic significance, the plastic moulding process offers numerous advantages that enhance production capabilities. The process allows for high-volume production, ensuring consistency and precision in each piece manufactured. Moreover, advancements in technology have improved the energy efficiency of moulding processes, reducing waste and minimizing environmental impacts. The Plastics Industry Association highlights that the U.S. plastics industry has made significant strides in sustainability, with a reported 95% of waste generated during the production phase being recycled or repurposed. This shift not only contributes to cost reduction but also aligns with global sustainability goals, making the plastic moulding process an increasingly attractive option for manufacturers looking to optimize both their operations and their environmental footprints.

Improved Efficiency and Cost-Effectiveness in Production

The plastic moulding process offers remarkable improvements in efficiency and cost-effectiveness, making it a preferred choice in various manufacturing sectors. According to a recent study by the American Society of Plastics Engineers, companies that utilize injection moulding can achieve production speeds up to 30% faster than traditional methods. This rapid turnaround not only shortens lead times but also allows manufacturers to respond quickly to market demands, ultimately enhancing their competitive edge.

Moreover, the cost-effectiveness of plastic moulding is underscored by industry data indicating that this process can reduce material waste by as much as 40%. Efficient use of materials directly translates to lower production costs, which can be crucial for businesses operating on tight margins. The ability to produce high-quality parts in large volumes with minimal rework or scrap contributes positively to the bottom line.

Additionally, advancements in moulding technologies have led to further reductions in energy consumption, with reports suggesting up to a 20% decrease in energy use per unit produced, reinforcing the sustainability and economic viability of adopting plastic moulding practices.

Versatility of Design: Customization and Complexity Made Easy

The versatility of the plastic moulding process has revolutionized industries by allowing for a wide range of design options, ensuring that customization and complexity are not just achievable but also efficient. One of the primary advantages of this process is the ability to create intricate shapes with precision. Designers are no longer limited by traditional methods; instead, they can harness advanced moulding techniques to bring complex geometries and fine details to life. This capability is particularly valuable in sectors such as automotive, consumer goods, and medical devices, where precise specifications are essential for functionality and aesthetics.

Furthermore, the plastic moulding process encourages innovation by enabling rapid prototyping and iteration. Designers can quickly test and modify their concepts without substantial investment in materials or time. This flexibility means that they can experiment with various designs, colors, and textures to meet the specific preferences of their target market. As a result, businesses can respond swiftly to changing consumer demands and trends, making the moulding process an invaluable asset in the competitive landscape. Through its inherent adaptability, the plastic moulding process not only facilitates sophisticated design solutions but also paves the way for ongoing creativity and advancement in product development.

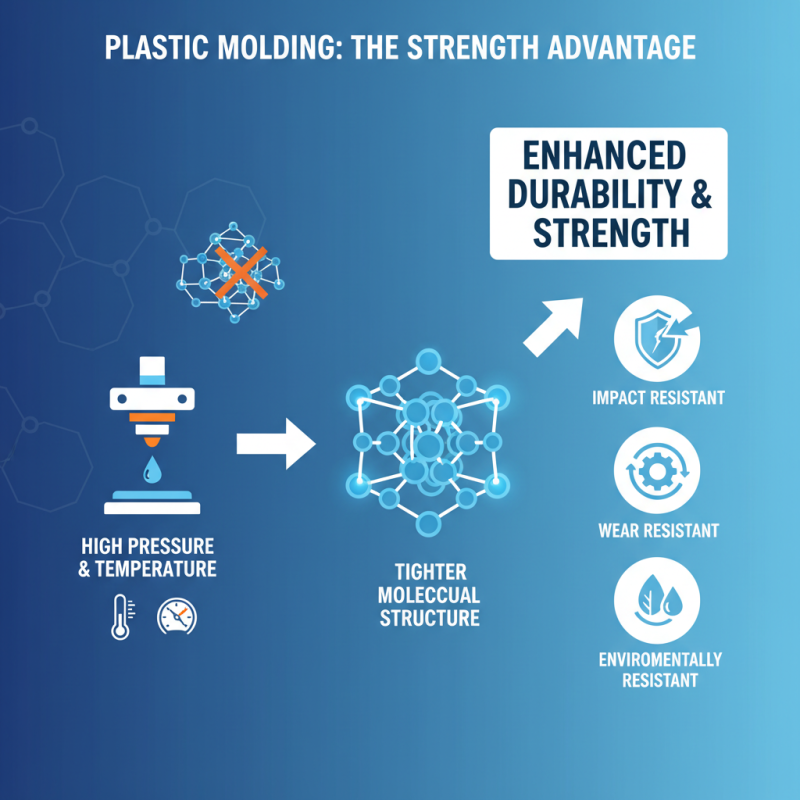

Enhanced Durability and Strength of Molded Products

The plastic moulding process has gained considerable popularity due to its ability to produce items that exhibit enhanced durability and strength. This is primarily achieved through the precise control over the material's composition and the moulding conditions. When plastic is subjected to high pressure and temperature during the moulding process, it results in a tighter molecular structure. This not only contributes to the toughness of the final product but also makes it resistant to wear, impact, and various environmental factors.

Moreover, the durability of molded products extends their lifecycle, providing a cost-effective solution for industries ranging from automotive to consumer goods. This reduction in material fatigue and failure rates means that products can withstand challenging conditions without compromising functionality. The combination of improved strength and longevity makes plastic moulding an ideal choice for creating components that demand high performance over time, ensuring that they meet the rigorous demands of modern applications.

Environmental Benefits: Sustainability in Plastic Moulding

The plastic moulding process plays a significant role in promoting environmental sustainability. One of the foremost benefits is the efficient use of materials. Advanced techniques in moulding, such as injection and blow moulding, allow manufacturers to optimize their designs, resulting in minimal waste during production. This efficiency not only saves costs but also significantly reduces the amount of plastic waste generated, contributing to a more sustainable production cycle.

Moreover, the plastic moulding industry is increasingly adopting recyclable materials. Many manufacturers are now utilizing recycled plastics in their moulding processes, which helps decrease dependency on virgin plastic and lowers the carbon footprint associated with production. This shift not only supports the circular economy but also encourages the development of more environmentally friendly practices within the industry.

By choosing sustainably sourced materials and implementing recycling initiatives, the plastic moulding process demonstrates a commitment to ecological responsibility while still meeting the growing demand for plastic products.

Related Posts

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

Why Understanding the Plastic Moulding Process is Essential for Manufacturers

-

Top 10 Benefits of Injection Moulding for Efficient Manufacturing

-

10 Best Rigid PVC Applications You Need to Know in 2023