How to Master Plastic Injection Moulding Techniques for Beginners?

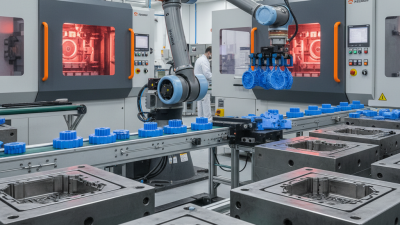

Plastic injection moulding is a vital manufacturing process widely used in various industries. According to the Plastics Industry Association, the U.S. plastics industry employed over 1 million workers in 2022. This huge workforce plays a crucial role in producing high-quality parts efficiently. However, mastering plastic injection moulding techniques remains a challenge for many beginners.

Many newcomers face difficulties with tooling and material selection. For example, choosing the right resin can significantly impact part quality and production cost. Industry reports indicate that improper material selection can lead to a 15% increase in production defects. Understanding the nuances of machine settings and cycle times is also essential. Even a slight adjustment can yield different outcomes.

This journey of mastering plastic injection moulding is not without its pitfalls. Beginners often overlook the importance of cooling time, resulting in warping and inconsistent finish. Realizing these points requires a reflective mindset. By acknowledging these challenges and seeking knowledge, beginners can gradually refine their skills. Embracing the learning curve is key to success in this dynamic field.

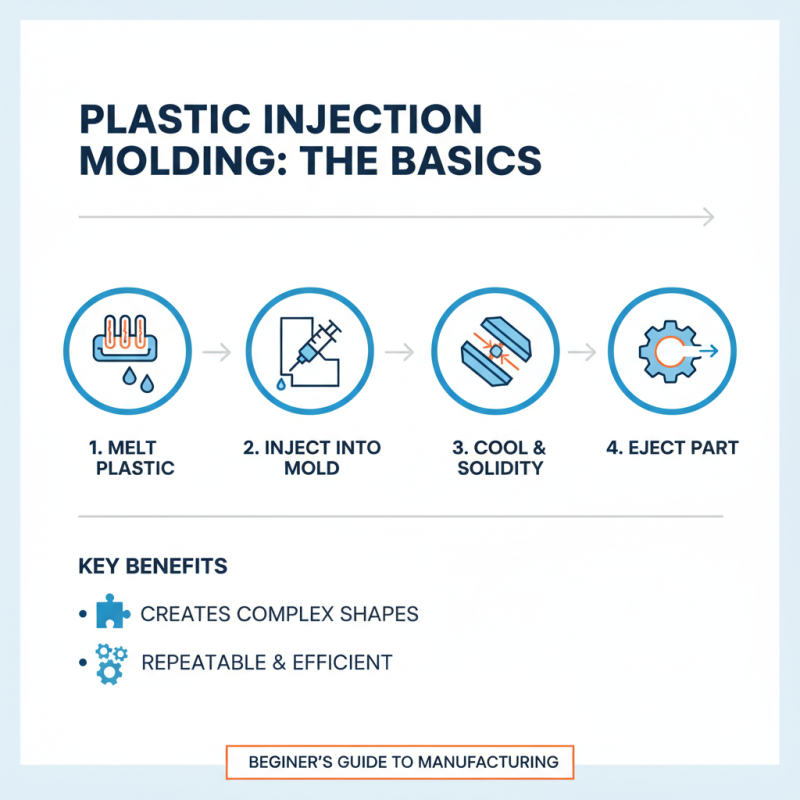

Understanding the Basics of Plastic Injection Moulding

Plastic injection moulding is a fascinating process. It involves forcing molten plastic into a specially designed mould. This technique can create intricate shapes and unique designs. For beginners, understanding the basics is crucial.

The first step is to learn about the materials used. Different plastics offer various properties, such as flexibility and strength. Experimenting with these materials is essential. Each type behaves differently when heated and cooled. Observing these differences helps in making informed decisions.

Next, consider the mould design. A well-designed mould can greatly affect the quality of the finished product. Imperfect moulds can lead to defects, like air bubbles or uneven surfaces. It’s a common pitfall. To improve, beginners should practice creating simple designs. Mistakes will happen, and that's part of the learning journey. Taking time to reflect on those mistakes will lead to better future projects.

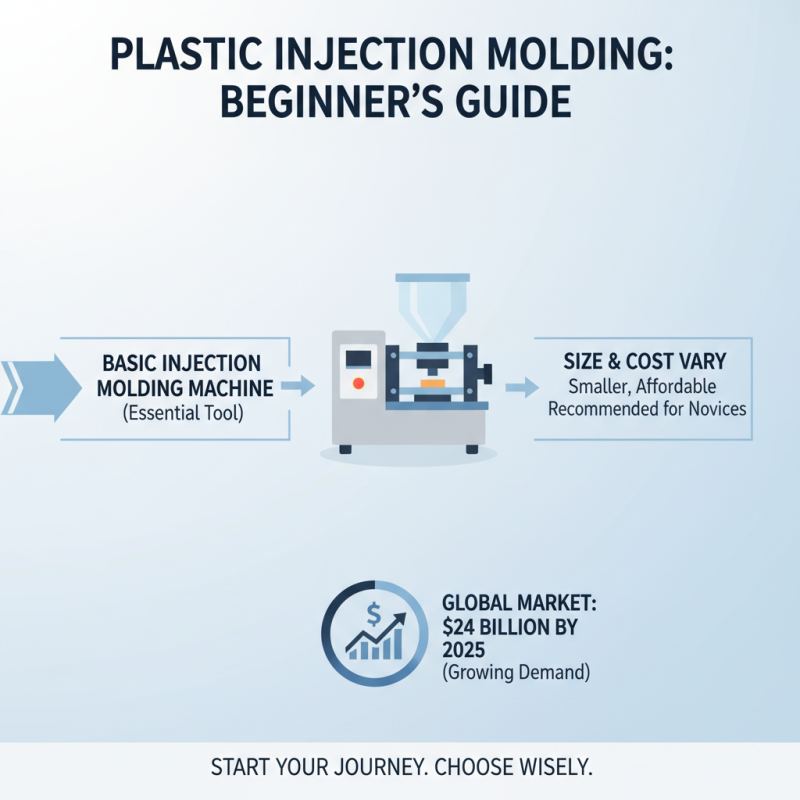

Essential Tools and Equipment for Beginners in Moulding

When starting your journey in plastic injection moulding, having the right tools is critical. A basic injection moulding machine is necessary. This equipment can vary greatly in size and cost. Beginners may find smaller, more affordable models easier to manage. According to recent industry reports, the global injection moulding machine market is projected to reach $24 billion by 2025. This reflects growing demand and the need for accessible machinery for novices.

In addition to the machine, essential tools include moulds, temperature controllers, and pressure gauges. Moulds can be custom-designed or purchased. Beginners often face challenges in creating effective mould designs. A poorly designed mould can lead to defects. It's important to invest in quality components. Furthermore, heating and cooling systems are crucial for controlling material flow and solidification. Failure to regulate these factors can result in inconsistent products.

While these tools are fundamental, experience plays a significant role. Many beginners overlook the importance of proper maintenance. Neglecting maintenance can lead to costly repairs or downtime. Observing the intricacies of the process is vital. Each step, from material selection to cooling, impacts the final product quality. Embracing the learning curve is essential for success in this intricate field.

Step-by-Step Guide to Designing Injection Moulds

Designing injection moulds can be daunting for beginners. Understanding the basics helps. Start by selecting suitable materials. Remember, the type of plastic influences your design choices. A strong mould will yield better parts. Take time to sketch your ideas. Visualizing your design is crucial.

Tips: Always keep material shrinkage in mind. It can affect the final product dimensions. Also, ensure the parting line allows for easy removal. Each detail matters.

Don't forget to consider cooling channels. Effective cooling speeds up production. Poor design might lead to warping. Testing prototypes is necessary. Learn from the mistakes made. Iterate and refine your mould designs. Each failure teaches you something valuable.

Plastic Injection Moulding Techniques Mastery: Skill Levels of Beginners

Common Materials Used in Plastic Injection Moulding

Plastic injection moulding is a popular manufacturing technique. Understanding common materials used can help beginners significantly.

Thermoplastics are widely used. They can be remolded multiple times. This characteristic is beneficial for various applications. Common types include polypropylene, polyethylene, and polystyrene. Each material has unique properties and applications. For example, polypropylene is tough and resistant to chemicals.

Some beginners may struggle with material selection. Not all plastics are suitable for every project. It can be challenging to balance flexibility and strength. Additionally, improper temperatures can affect material properties. Understanding these nuances is essential for successful moulding. Experimentation is often key. It's normal to make mistakes in the learning process. Adjusting parameters will lead to better outcomes over time.

How to Master Plastic Injection Moulding Techniques for Beginners? - Common Materials Used in Plastic Injection Moulding

| Material | Type | Melting Temperature (°C) | Applications |

|---|---|---|---|

| Polypropylene (PP) | Thermoplastic | 160-200 | Containers, automotive parts, and fibers |

| Acrylonitrile Butadiene Styrene (ABS) | Thermoplastic | 220-250 | Lego bricks, kitchen appliances, and electronic housings |

| Polyethylene (PE) | Thermoplastic | 110-130 | Plastic bags, bottles, and toys |

| Polyvinyl Chloride (PVC) | Thermoplastic | 160-200 | Pipes, fittings, and medical equipment |

| Polycarbonate (PC) | Thermoplastic | 230-260 | Safety goggles, electronic components, and automotive parts |

Troubleshooting Common Issues in Injection Moulding Processes

Injection moulding is a complex process. Beginners often face common issues that can disrupt production. Understanding these problems is key to mastering this technique.

One common issue is poor mould filling. This can lead to incomplete parts. It's crucial to check the temperature and the speed of injection. If the material is too cold, it may not flow properly. Adjusting these parameters can often resolve the issue.

Tips: Always ensure your machine settings match the specifications of the material. Test different temperatures to find the optimal level.

Another issue is warping. Parts can change shape after cooling. This can be caused by uneven cooling. A balanced cooling system helps maintain part integrity. Monitor your cooling channels regularly to avoid this.

Tips: Use consistent wall thickness in your designs. This can reduce the risk of warping significantly.

Lastly, air traps can create defects in parts. They occur when air gets trapped in the mould. This leads to weak or compromised areas in the final product. Regularly inspect your designs to ensure proper venting.

Tips: Incorporate air vents in your mould design. This will help release trapped air during the injection process.

Related Posts

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

Top 5 Benefits of Injection Tooling for Efficient Manufacturing Process

-

2025 Trends in Mold Injection Molding: Innovations and Market Insights

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

10 Best Rigid PVC Applications You Need to Know in 2023

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry