10 Essential Tips for Mastering Injection Moulding Techniques

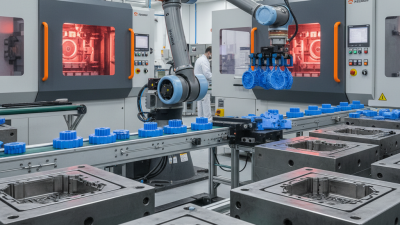

Injection moulding is a transformative technology that forms the backbone of modern manufacturing, allowing for the production of complex shapes with high precision and efficiency. As industries seek to optimize their processes and reduce costs, mastering the techniques associated with injection moulding becomes increasingly crucial for engineers and manufacturers alike. This article presents ten essential tips that aim to enhance understanding and execution of injection moulding practices, enabling professionals to achieve superior results.

The world of injection moulding is intricate, encompassing a range of variables and parameters that can significantly influence the quality of the final product. From material selection to temperature control, each aspect of the injection moulding process requires careful consideration. By applying these expert-recommended tips, practitioners can refine their skills, troubleshoot common issues, and ultimately unlock the full potential of injection moulding. Whether you are a seasoned professional or a newcomer to the field, this guide will provide valuable insights to help you navigate the complexities of injection moulding effectively.

Understanding the Basics of Injection Moulding

Injection moulding is a pivotal manufacturing process widely used in the production of plastic parts. Understanding the basics of this technique is crucial for anyone looking to master its intricacies. The process involves injecting molten material into a mould to produce items with high precision and repeatability. According to a report by MarketsandMarkets, the global injection moulding market is expected to grow from USD 259 billion in 2020 to USD 394 billion by 2026, highlighting its importance in various industries such as automotive, consumer goods, and medical devices.

At its core, injection moulding comprises several key components: the hopper, screw, barrel, and mould. Each of these elements plays a critical role in ensuring that the molten plastic is injected optimally. The temperature, pressure, and timing must be carefully controlled to avoid defects such as warping or short shots. Industry data shows that approximately 30% of production issues in injection moulding stem from improper settings, making it essential to understand the fundamentals before delving deeper into advanced techniques. Mastering these basics allows for better troubleshooting and optimization of the production process, ultimately enhancing quality and efficiency.

Key Factors Influencing Injection Moulding Quality

The quality of injection moulding is significantly influenced by several key factors, which can determine the success of the final product. One of the primary elements is the selection of materials used in the process. Different plastics have varying properties, such as melting temperature, viscosity, and shrinkage rates. Understanding these characteristics can help in choosing the right material that meets the specific requirements of the final product, ensuring optimal flow and solidification during the injection cycle.

Another critical factor is the accuracy of the machine settings, including temperature, pressure, and speed. These parameters must be meticulously calibrated to maintain consistency and prevent defects, such as incomplete filling or warping. The mould design itself plays a crucial role, as it should facilitate uniform material distribution and ease of ejection. Moreover, regular maintenance of both the machinery and the mould is essential to sustain quality output over time. By focusing on these aspects, manufacturers can significantly enhance the quality of their injection moulding processes, leading to better final products.

Injection Moulding Quality Factors

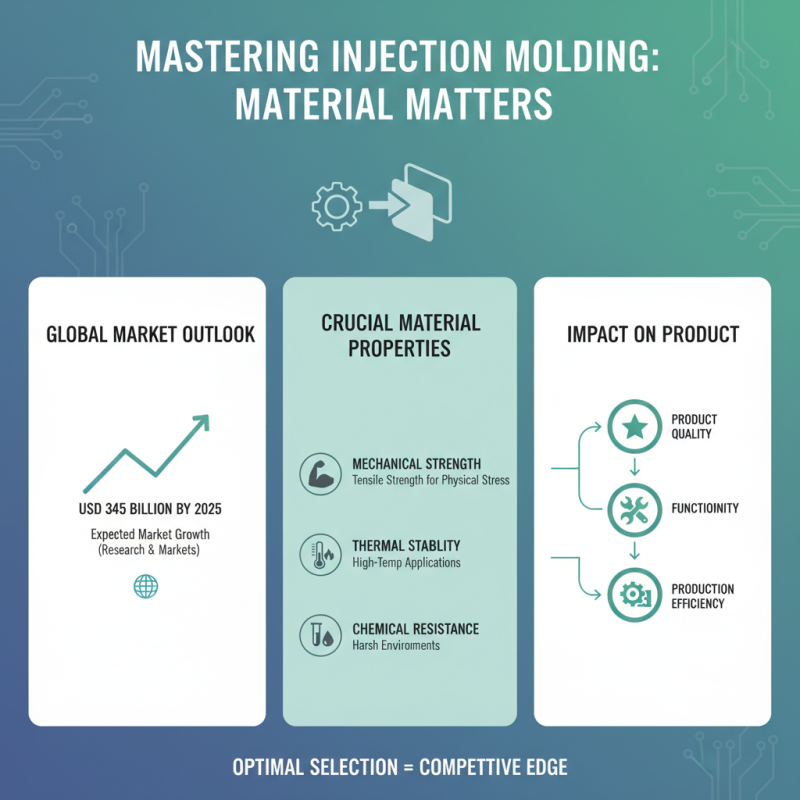

Essential Techniques for Optimal Material Selection

Choosing the right materials is crucial in mastering injection moulding techniques, as it significantly influences the product's quality, functionality, and production efficiency. According to a report by Research and Markets, the global injection moulding market is expected to reach USD 345 billion by 2025, emphasizing the importance of selecting optimal materials to stay competitive. Factors such as mechanical properties, thermal stability, and chemical resistance play vital roles in material selection. For example, materials with higher tensile strength are often ideal for products that must withstand physical stress, while those with excellent thermal properties are preferred for high-temperature applications.

Additionally, understanding the properties and behavior of different polymers is essential for achieving superior results in injection moulding. A study published in the Journal of Materials Science found that materials like polypropylene provide a balance of strength and flexibility, making them suitable for a wide range of applications. Conversely, high-performance thermoplastics such as PEEK offer exceptional temperature resistance and durability, suitable for specialized industries. Data from the Plastics Industry Association indicates that over 80% of manufacturers report that material costs significantly impact their overall production expenses, reinforcing the necessity for strategic material selection to optimize both cost and performance in injection moulding processes.

Troubleshooting Common Injection Moulding Issues

Common issues in injection moulding can significantly impact production efficiency and product quality. According to a study by the Plastics Industry Association, around 50% of injection moulding defects are attributable to material issues, which often stem from improper drying procedures or incorrect material selection. To alleviate such problems, it's crucial to conduct thorough drying and conditioning of polymer materials before processing. For instance, nylon and polycarbonate require specific moisture contents, and exceeding these thresholds can lead to issues such as splay or voids in the finished product.

Another prevalent challenge in the injection moulding process is short shots, where the mould is not completely filled. This can be caused by low pressure or insufficient injection speed. Data from the Society of Plastics Engineers indicates that around 35% of short shot occurrences are due to inadequate venting in the mould designs. Implementing enhanced venting solutions can dramatically improve the filling process, ensuring the mould cavity is filled completely and that production downtime is minimized. By early identification and rectification of these common issues, manufacturers can not only improve their production yields but also enhance the overall quality of their plastic components.

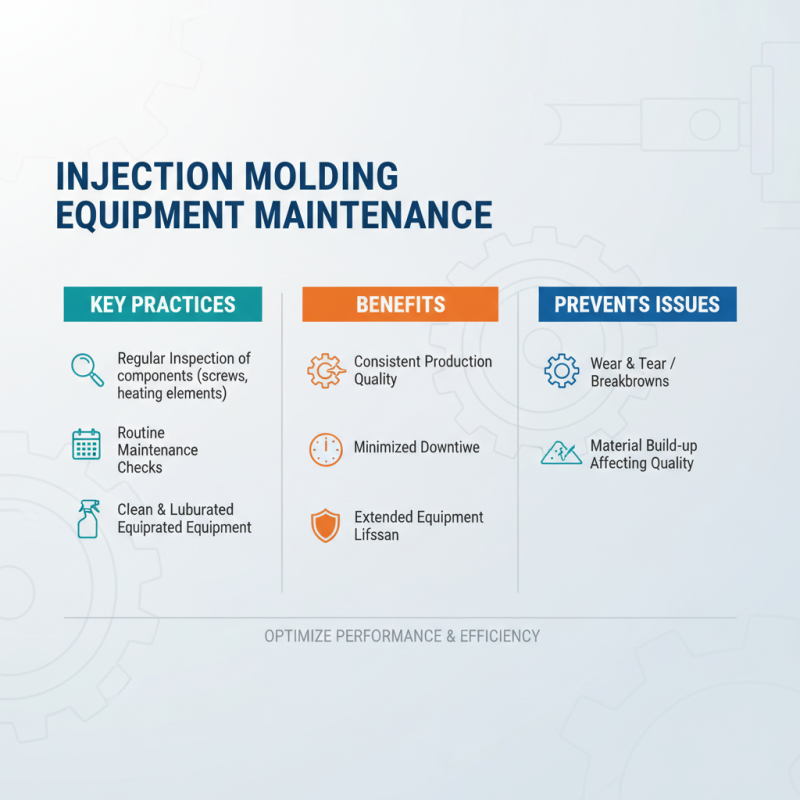

Best Practices for Maintaining Injection Moulding Equipment

Maintaining injection moulding equipment is crucial for ensuring consistent production quality and efficiency. Regular inspection of machine components, such as screws, nozzles, and heating elements, helps to identify wear and tear before it leads to significant issues. Scheduling routine maintenance checks not only extends the lifespan of the equipment but also minimizes downtime, allowing for smoother operations. Additionally, keeping the equipment clean and lubricated contributes to optimal performance and can prevent material build-up that may affect the quality of the final product.

Another essential practice involves monitoring processing conditions closely. This includes maintaining appropriate temperature and pressure settings to ensure adequate material flow and curing. Operators should be trained in how to adjust these settings based on the specific materials being used and the desired characteristics of the molded parts. Implementing a systematic approach to data collection and analysis can aid in identifying trends that may require adjustments in the process or equipment. By adopting these best practices, manufacturers can enhance the reliability of their injection moulding processes and produce high-quality parts consistently.

Related Posts

-

Top 5 Benefits of Injection Tooling for Efficient Manufacturing Process

-

Why Plastic Granules Are the Key to Sustainable Manufacturing and Recycling

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

Understanding the Impact of Injection Molding Pellets on Sustainable Manufacturing Practices

-

2025 How to Choose the Best PVC Moulding Machine for Your Business

-

10 Essential Tips for Selecting Rigid PVC Pipe: Maximize Durability and Performance Based on Industry Standards