Why Choose PVC Pellets for Injection Molding in Your Manufacturing Process

In the ever-evolving landscape of manufacturing, choosing the right materials can significantly impact both efficiency and product quality. PVC pellets for injection molding have emerged as a popular choice among manufacturers due to their versatility and reliability. According to Dr. Emily Roberts, a leading expert in polymer science, "The use of PVC pellets for injection molding offers manufacturers a unique blend of durability and ease of processing, making it an ideal choice for a wide range of applications." This underscores the growing acceptance of PVC in the industry, driven by advancements in formulation technologies that enhance its performance.

The benefits of utilizing PVC pellets for injection molding are manifold. Not only do they provide excellent mechanical strength and resistance to environmental factors, but they also allow for efficient processing under various molding conditions. As industries continue to demand materials that can keep up with rigorous standards, PVC pellets stand out for their ability to meet these needs without compromising on quality. By adopting PVC as a key material in their processes, manufacturers can ensure the production of robust and long-lasting products, ultimately leading to increased customer satisfaction and improved market competitiveness.

The Versatility of PVC Pellets in Injection Molding Applications

PVC (Polyvinyl Chloride) pellets have become a cornerstone in the injection molding landscape due to their remarkable versatility across various applications. According to recent industry reports, PVC is among the top three thermoplastic materials used in injection molding, valued for its excellent durability, resistance to environmental factors, and ease of processing. This material is notable for its adaptability, making it suitable for a wide range of products, from consumer goods to automotive components. Its unique properties allow for customization, enabling manufacturers to achieve specific performance characteristics depending on their project requirements.

Tips for maximizing the application of PVC pellets in your manufacturing process include ensuring optimal temperature settings during the injection molding process, as PVC requires precise thermal control to maintain its integrity and prevent degradation. Additionally, consider incorporating additives that can enhance characteristics such as UV resistance and impact strength, which broaden the material's application range even further. Reports indicate that using blended formulations can improve functionality and overall product performance significantly.

Moreover, PVC’s lightweight nature contributes to reduced shipping costs and energy savings during transportation, according to studies from industry analysts. By adopting PVC pellets in your injection molding applications, you can not only benefit from cost-effective production but also meet the growing demands of sustainability within manufacturing sectors. Coating and plasticizing techniques can further expand the usability of PVC, allowing manufacturers to explore innovative designs and applications with relative ease.

Key Advantages of PVC Pellets Compared to Other Materials

PVC pellets have gained significant recognition in the injection molding sector due to their numerous advantages over other materials. One of the key benefits is their excellent versatility, which allows manufacturers to tailor the properties of the final product to meet specific requirements. According to a report by the Plastics Industry Association, PVC accounts for approximately 20% of the global thermoplastic market, largely due to its adaptability, ease of processing, and cost-effectiveness. The material exhibits good mechanical strength, chemical resistance, and durability, making it suitable for a wide range of applications, from construction to consumer goods.

In addition to their versatility, PVC pellets stand out due to their lower environmental impact compared to alternatives like ABS or polystyrene. A recent study published in the Journal of Cleaner Production indicated that PVC production typically results in lower greenhouse gas emissions, making it a more sustainable option for manufacturers. The potential for recyclability further enhances PVC's sustainability profile, allowing companies to minimize waste and contribute to a circular economy.

**Tips:** When selecting materials for your injection molding process, consider the specific properties required for your application. Conduct comparative analyses to understand the lifecycle impacts of different materials. Moreover, engage with local recycling programs to optimize the sustainability of your manufacturing practices.

Why Choose PVC Pellets for Injection Molding in Your Manufacturing Process - Key Advantages of PVC Pellets Compared to Other Materials

| Feature | PVC Pellets | Other Materials (e.g., ABS, Polypropylene) |

|---|---|---|

| Cost-Effectiveness | Generally lower material costs and competitive pricing | Higher costs for raw materials |

| Durability | Excellent resistance to impact and environmental stress | Good but can be susceptible to environmental factors |

| Versatility | Can be easily modified to fit various applications | Less flexible in modifications |

| Processing Ease | Easily processed using standard injection molding techniques | May require specialized processing conditions |

| Environmental Resistance | Highly resistant to moisture, chemicals, and UV exposure | Varies significantly by material |

| Weight | Lighter than many other polymers | Typically heavier, impacting shipping costs |

| Recyclability | Recyclable with proper facilities | Some can be more difficult to recycle |

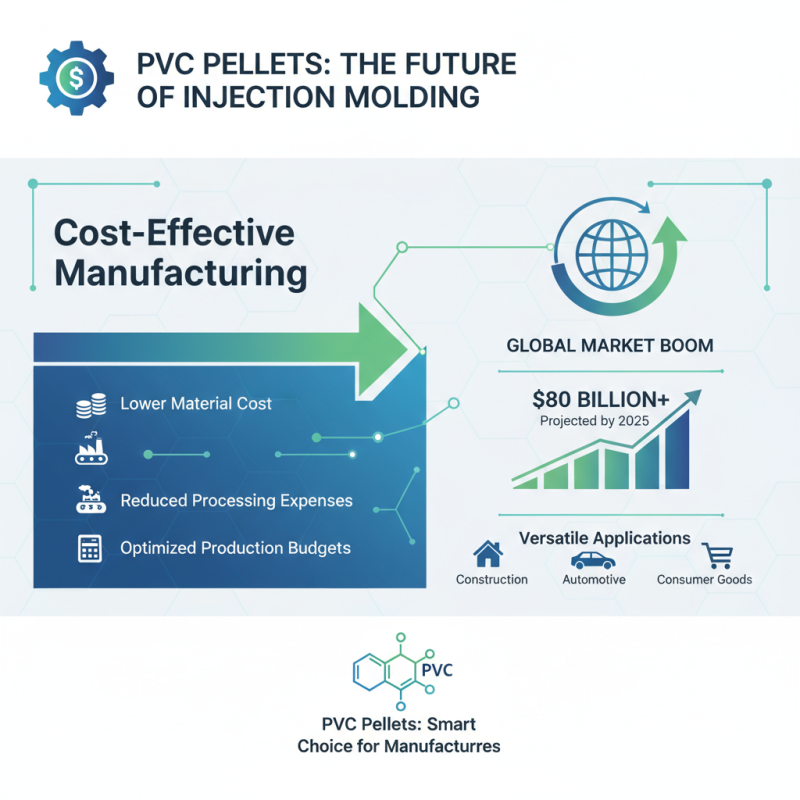

Cost-Effectiveness of PVC Pellets in Large-Scale Manufacturing

The use of PVC pellets in injection molding has gained prominence in large-scale manufacturing due to their cost-effectiveness. According to recent industry reports, the global PVC market is projected to reach over $80 billion by 2025, reflecting a significant demand due to the material’s versatile applications in various sectors, including construction, automotive, and consumer goods. PVC pellets not only offer a lower initial material cost but also contribute to savings in processing expenses, making it a compelling choice for manufacturers looking to optimize their production budgets.

In large-scale operations, the efficiency of manufacturing processes is crucial. The processing temperatures of PVC are generally lower compared to other thermoplastics, which can lead to reduced energy consumption during production. A report from the American Plastics Council indicates that thermoplastic materials, such as PVC, can improve the overall energy efficiency of molding processes by up to 30%. Additionally, the recyclability of PVC pellets further enhances their cost-effectiveness, as manufacturers can reintegrate scrap material back into their production lines, minimizing waste and lowering material costs in the long run. This sustainable approach not only supports environmental goals but also strengthens the economic viability of using PVC in large-scale manufacturing settings.

Environmental Impact and Sustainability of PVC Pellets Usage

The use of PVC pellets in injection molding has garnered attention not only for their performance advantages but also for their environmental impact and sustainability. According to the Plastics Industry Association, PVC has one of the lowest carbon footprints among thermoplastic materials, primarily due to its efficient recycling capabilities. Recent studies indicate that more than 70% of PVC products can be recycled effectively, contributing to a circular economy and reducing the need for virgin materials. This recycling potential significantly lessens environmental effects, making PVC a compelling choice for manufacturers looking to minimize their carbon footprint.

Moreover, the sustainability of PVC pellets is enhanced by the increasing advancements in production processes. Research conducted by the European PVC industry shows that modern production methods have led to a 20% reduction in harmful emissions from PVC production over the past decade. These innovations not only improve the material’s overall sustainability profile but also reassure manufacturers that they are investing in a product with lower environmental risks. As companies prioritize eco-friendly practices, PVC pellets emerge as a favorable option that aligns with sustainable manufacturing goals while maintaining performance and cost-effectiveness.

Environmental Impact and Sustainability of PVC Pellets Usage in Injection Molding

Industry Trends: Increasing Demand for PVC in Injection Molding Processes

The demand for PVC in injection molding processes is on the rise, driven by its versatility and cost-effectiveness. As industries seek materials that can offer both durability and flexibility, PVC stands out as a preferred choice. Its properties allow manufacturers to create complex shapes with precision and a high-quality finish, making it suitable for a variety of applications, including automotive parts, consumer goods, and medical devices. This shift towards PVC reflects a broader trend within the manufacturing sector, where efficiency and sustainability are increasingly prioritized.

Moreover, advancements in technology have enhanced the processing capabilities of PVC pellets, allowing for better melt flow and improved mechanical properties during molding. This evolution in PVC formulations caters to the growing needs of manufacturers looking for reliable solutions that meet stringent regulatory requirements while reducing waste. As sustainability becomes a key focus, PVC's recyclability and long lifespan contribute to its appeal, encouraging further investment in PVC-based production methods. The increasing integration of PVC in injection molding processes illustrates a pivotal shift in manufacturing strategies aimed at enhancing performance and meeting market demands.

Related Posts

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

Why Understanding the Plastic Moulding Process is Essential for Manufacturers

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

10 Essential Tips for Selecting Rigid PVC Pipe: Maximize Durability and Performance Based on Industry Standards

-

Top Uses of Plastic Raw Material in Modern Industries and Their Impact

-

What is Plastic Raw Material Types and Their Applications