How to Choose the Best Injection Moulded Parts for Your Project in 2025

As we move into 2025, the demand for high-quality injection moulded parts continues to grow across various industries, from automotive to consumer goods. The ability to choose the right parts can greatly affect a project's success, influencing factors such as product durability, manufacturing efficiency, and cost-effectiveness. Industry expert Dr. Emily Carter, a renowned figure in the field of polymer engineering, emphasizes, "Selecting the appropriate injection moulded parts is not just about meeting specifications; it’s about enhancing the overall performance of the final product."

When considering the best injection moulded parts for your project, it's crucial to evaluate several factors, including material properties, design complexity, and the intended application. The right choices can drive innovation and improve product reliability, ensuring that you remain competitive in a rapidly evolving market. With advancements in technology and materials science, the landscape of injection moulding is constantly changing, making it imperative for designers and engineers to stay informed.

In this guide, we will delve into the essential criteria and practical tips for selecting the best injection moulded parts, helping you make informed decisions that align with your project goals. Whether you are developing new prototypes or refining existing products, understanding the nuances of injection moulded parts can provide significant advantages and pave the way for successful outcomes.

Understanding Injection Moulding and Its Applications in 2025

Injection moulding is a versatile manufacturing process widely used across various industries, including automotive, healthcare, and consumer goods. In 2025, the significance of injection moulding is anticipated to grow even further due to advancements in technology and materials. This process involves injecting molten material into a mould to create precise and complex components, allowing for enhanced design flexibility and efficiency in production. With an increasing demand for lightweight and durable parts, the application of innovative polymers and composites in injection moulding is revolutionizing product development.

As industries evolve, understanding the applications of injection moulding becomes paramount for successful project planning. In 2025, considerations such as sustainability and cost-effectiveness will play a crucial role in selecting injection moulded parts. This may include opting for biodegradable materials or integrating smart manufacturing techniques that reduce waste. Furthermore, customization in design and functionality will enable businesses to meet specific client requirements more effectively, fostering innovation and competitiveness in the market. By comprehensively understanding these aspects, project leaders can make informed decisions that align with future trends and demands in the manufacturing landscape.

Key Factors to Consider When Choosing Injection Moulded Parts

When selecting injection moulded parts for your project in 2025, several key factors must be taken into account to ensure optimal performance and cost-efficiency. One of the primary considerations is material choice. With advancements in polymer science, materials such as high-performance thermoplastics are gaining traction, offering enhanced mechanical properties and durability. According to a report by MarketsandMarkets, the global injection molding market is projected to reach USD 300 billion by 2025, driven largely by the growing demand for lightweight materials in automotive and consumer goods sectors. Understanding the specific requirements of your application will help in choosing the right material that balances cost with functionality.

Another critical factor is the design of the parts themselves. Utilizing design for manufacturability (DFM) principles can significantly influence production speed and reduce waste. Ensuring that your designs incorporate best practices, such as appropriate wall thickness, ribbed structures for strength, and minimized draft angles, can yield parts that not only meet performance specifications but are also cost-effective to produce. A study by Grand View Research indicated that incorporating DFM can reduce costs by up to 20%, demonstrating how strategic design choices contribute to efficiency in the injection moulding process. By carefully considering these factors, you can make informed decisions that align with your project goals for the upcoming year.

Injection Moulded Parts Material Selection in 2025

Evaluating Material Options for Injection Moulded Parts in 2025

When evaluating material options for injection moulded parts in 2025, it is essential to consider the evolving needs of sustainability and performance. Advanced materials such as bio-based plastics and engineering thermoplastics offer exciting alternatives that combine durability with environmental consciousness. These materials not only support a reduction in carbon footprints but also provide the necessary mechanical properties to withstand the demands of various applications, whether in automotive, consumer products, or medical devices.

Furthermore, understanding the specific requirements of your project can help narrow down material choices. Factors such as temperature resistance, chemical compatibility, and weight considerations play a vital role in the selection process. In addition, new technologies in material processing may contribute to improved performance characteristics, including enhanced strength and flexibility. As manufacturing methods advance and new innovations come to the forefront, selecting the right material will involve a careful balance of functionality, sustainability, and cost-effectiveness, ensuring that the final product meets both current standards and future expectations.

Assessment of Production Costs and Time in Injection Moulding

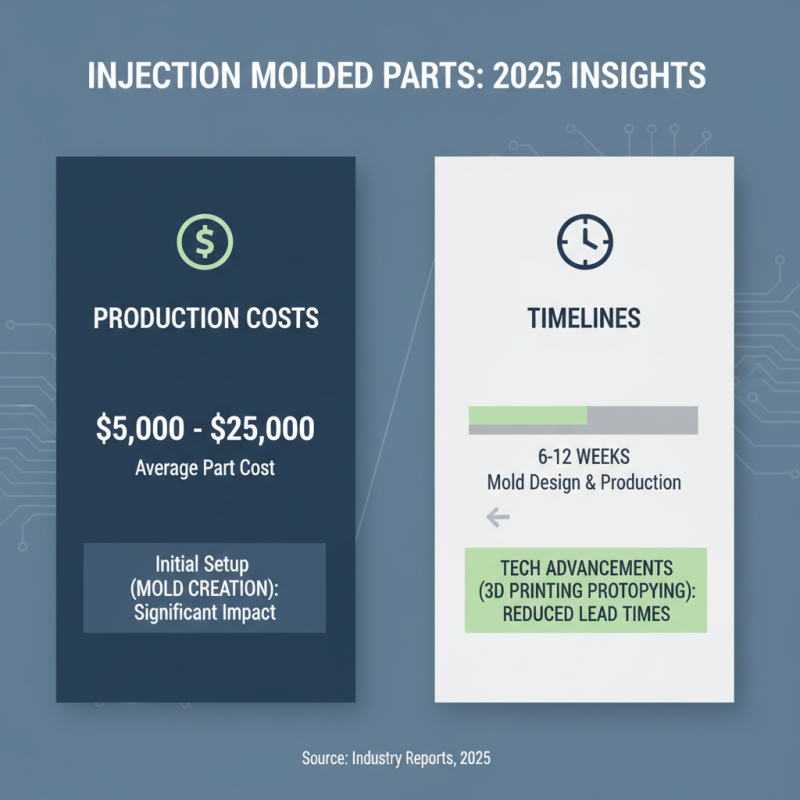

When selecting injection moulded parts for your project in 2025, understanding production costs and timelines is crucial. According to recent industry reports, the average cost of injection moulding ranges between $5,000 to $25,000 depending on the complexity of the part and the materials used. Notably, the initial setup costs, including mould creation, can significantly impact the overall budget. The average lead time for mould design and production has been reported at approximately 6 to 12 weeks. However, advancements in technology, such as the use of 3D printing for prototyping, are reducing these timelines dramatically.

Moreover, it’s important to consider the economies of scale in injection moulding. As production volumes increase, the cost per part decreases, leading to cost-efficient manufacturing solutions. For low-to-medium volume runs, the per-unit cost can range from $1 to $10, while high volumes may drop to as low as $0.10 per unit. Although the initial costs may be daunting, the long-term savings in production and material efficiency can justify the investment. A detailed analysis of these factors is essential for making informed decisions about injection moulded parts that align with your project's goals and budget constraints.

Exploring Quality Control Standards for Injection Moulded Components

When selecting injection moulded components for your project in 2025, understanding quality control standards is paramount. Injection moulding is a widely used process in manufacturing, and ensuring high-quality parts can significantly impact the performance and longevity of your products. According to a 2023 report by the International Organization for Standardization (ISO), nearly 70% of manufacturers have reported an increase in defects due to insufficient quality control measures. This highlights the importance of utilizing rigorous standards to maintain product integrity.

Quality control in injection moulding encompasses several key criteria, including material selection, process monitoring, and post-production inspections. The American Society for Testing and Materials (ASTM) recommends thorough testing protocols, such as ASTM D638 for tensile strength and ASTM D790 for flexural properties, to guarantee that the materials used meet the necessary specifications. Additionally, incorporating automated inspection systems can enhance the consistency of results and reduce human error, as noted in a recent study by the Society of Plastics Engineers, which demonstrated a 30% reduction in defect rates when integrating automation.

As manufacturers aim for sustainability and efficiency, adherence to quality control standards is essential. A report by Grand View Research indicates that the global injection molding market is expected to reach USD 383.2 billion by 2030, driven in part by advancements in quality assurance technologies. By focusing on quality control, companies can not only improve product reliability but also enhance overall customer satisfaction and reduce long-term costs associated with defects and recalls.

Related Posts

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Injection Moulding for Efficient Manufacturing

-

Exploring the Versatility of Polyvinyl Chloride Material in Modern Applications

-

Why Plastic Granules Are the Key to Sustainable Manufacturing and Recycling

-

Top 10 Plastic Raw Materials Used in the Manufacturing Industry Today