10 Best Rigid PVC Applications You Need to Know in 2023

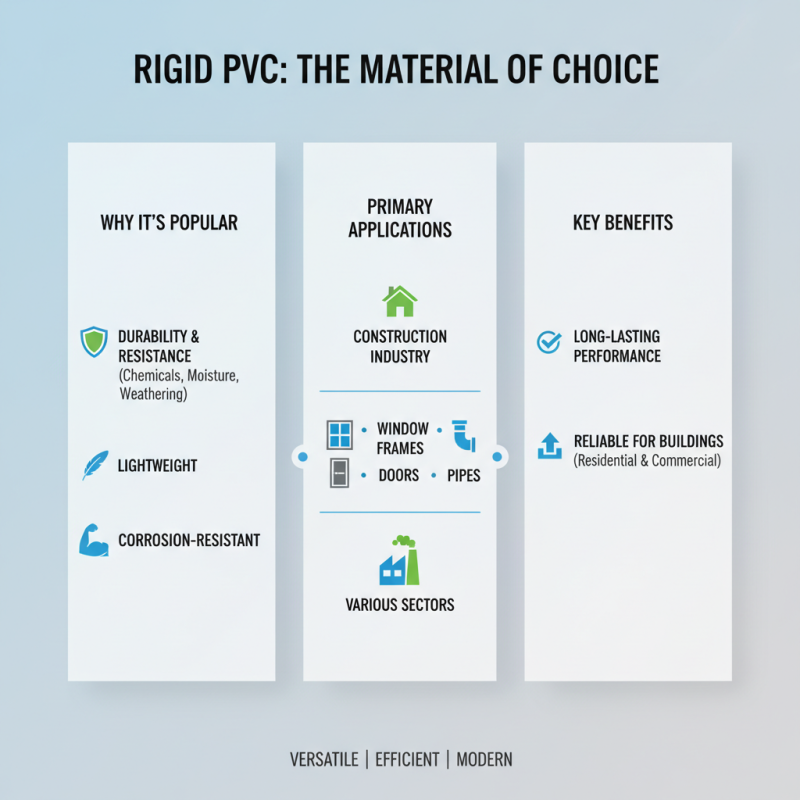

Rigid PVC, or polyvinyl chloride, is a versatile material known for its durability, lightweight properties, and resistance to moisture and chemicals. In 2023, the applications of rigid PVC have expanded significantly, making it a vital component across various industries. From construction to automotive, the unique characteristics of rigid PVC have made it the material of choice for manufacturers seeking reliable and cost-effective solutions.

The ability of rigid PVC to be easily molded and formed allows it to meet diverse application needs, leading to innovative uses that enhance functionality and efficiency. In this article, we will explore the ten best applications of rigid PVC that are transforming industries and providing solutions to everyday challenges. Understanding these applications will not only highlight the practicality of rigid PVC but also showcase its potential for future innovations. As we delve into these exciting developments, it becomes clear that rigid PVC is not just a material; it is a cornerstone of modern engineering and design, capable of adapting to the ever-changing demands of various sectors.

Understanding Rigid PVC: Definition and Properties

Rigid Polyvinyl Chloride (PVC) is an essential material in various industries due to its unique properties and versatility. Defined as a solid form of PVC that maintains its shape and rigidity, it is increasingly utilized in applications requiring durability, strength, and resistance to environmental factors. Rigid PVC has a high tensile strength and a low tensile elongation, making it ideal for structural applications. According to a report by Grand View Research, the global rigid PVC market is projected to reach USD 57.3 billion by 2028, demonstrating its growing demand across different sectors.

One of the defining characteristics of rigid PVC is its resistance to chemicals and moisture, which makes it suitable for construction materials such as window frames, doors, and pipes. In the electrical industry, it serves as an effective insulation material, providing safety and reliability in various installations. Furthermore, the material’s impressive fire-retardant properties enhance its appeal in sectors such as building and construction. The Plastics Industry Association indicates that roughly 80% of rigid PVC produced in North America is used for building and construction, highlighting its predominant role in these applications. As innovations in manufacturing processes continue to emerge, the scope of rigid PVC applications is set to expand even further, making it an essential material to understand in 2023.

10 Best Rigid PVC Applications You Need to Know in 2023

| Application | Industry | Benefits | Typical Uses |

|---|---|---|---|

| Construction | Building Materials | Durability and Weather Resistance | Pipes, Windows, and Doors |

| Electronics | Consumer Electronics | Insulative Properties | Covers, Enclosures, and Components |

| Automotive | Transportation | Lightweight and Strong | Interiors, Trim, and Panels |

| Medical | Healthcare | Chemical Resistance | Medical Devices, Tubing |

| Packaging | Consumer Goods | Versatile and Lightweight | Containers, Blisters |

| Signage | Advertising | High Clarity | Banners, Display Boards |

| Furniture | Interior Design | Maintenance-Free | Tables, Cabinets |

| Agriculture | Farming | Weather Resistant | Pipes, Greenhouse Frames |

| Consumer Products | Retail | Customization | Toys, Home Goods |

| Construction Accessories | Construction | Affordable and Easy to Work With | Fittings, Connectors |

Common Industries Utilizing Rigid PVC in 2023

Rigid PVC, known for its durability and versatility, finds extensive use across various industries in 2023. One of the primary sectors benefiting from Rigid PVC is construction. It is widely utilized in window frames, doors, siding, and piping systems due to its resistance to moisture and chemicals. These properties not only extend the lifespan of building materials but also contribute to energy efficiency, as Rigid PVC insulation helps reduce thermal conductivity.

Another significant industry leveraging Rigid PVC is healthcare. Its non-toxic and easily sterilizable nature makes it ideal for medical devices, tubing, and containers. Hospitals and clinics appreciate Rigid PVC's ability to withstand rigorous cleaning processes while maintaining structural integrity. Additionally, the packaging industry exploits Rigid PVC's clarity and strength for producing containers and blister packs, ensuring the safety and visibility of products ranging from pharmaceuticals to consumer goods. The ongoing demand for eco-friendly alternatives in packaging also encourages innovation in Rigid PVC applications, aligning with sustainability goals prevalent in many industries today.

Top 10 Applications of Rigid PVC in Various Sectors

Rigid PVC (Polyvinyl Chloride) has gained immense popularity across various sectors due to its durability, lightweight nature, and excellent resistance to chemicals and moisture. One of the most notable applications is in the construction industry, where it is widely used for window frames, doors, and pipes. The materials' resistance to corrosion and weathering makes it a reliable choice for both residential and commercial buildings, ensuring long-lasting performance.

In the medical field, rigid PVC plays a critical role in manufacturing medical devices and packaging. Its ability to be sterilized effectively allows for its use in products such as syringes, IV bags, and various disposable instruments, ensuring safety and hygiene in healthcare settings. Furthermore, in the automotive industry, Rigid PVC is employed in interior components, dashboards, and exterior trim, providing a versatile material that meets the demands for durability and aesthetic appeal. The versatility of rigid PVC continues to drive innovation and application expansion across diverse industries.

Advantages of Using Rigid PVC in Commercial Products

Rigid PVC, or polyvinyl chloride, has emerged as a popular choice for various commercial applications due to its unique set of advantages. One of the primary benefits of using rigid PVC is its exceptional durability. This material is resistant to impact, weather, and chemicals, making it ideal for outdoor signage, pipes, and construction materials. Its strength ensures that products made from rigid PVC maintain their structural integrity over time, reducing the need for frequent replacements and lowering long-term costs.

Another significant advantage is the versatility of rigid PVC. It can be easily molded into different shapes and sizes, which allows manufacturers to create customized solutions that meet specific needs in various industries, such as healthcare, construction, and packaging. Additionally, rigid PVC is lightweight, making it easier to transport and install compared to heavier materials. This combination of durability and adaptability makes rigid PVC an essential material in commercial products, helping businesses improve efficiency while delivering high-quality results.

Future Trends and Innovations in Rigid PVC Applications

In 2023, the rigid PVC industry continues to evolve, with a clear focus on innovative applications and sustainability. Recent data from the Plastics Industry Association indicate that the demand for rigid PVC is projected to grow by 4.5% annually, driven primarily by the construction and automotive sectors. As green building practices gain traction, rigid PVC's compatibility with sustainable design principles positions it as a favored material. Its durability, low maintenance, and energy efficiency make it an excellent choice for window profiles, siding, and roofing membranes, significantly reducing the environmental footprint of modern buildings.

Future trends indicate a surge in the adoption of rigid PVC in the healthcare sector, where its antimicrobial properties and ease of sterilization are becoming increasingly crucial. A report from Allied Market Research highlights that the healthcare industry is anticipated to be a key growth driver for rigid PVC, especially in applications such as medical devices and packaging, which are expected to see a compound annual growth rate (CAGR) of 5.8% through 2026. Innovations in formulation and production technology are paving the way for more versatile and higher performance rigid PVC products, enhancing their appeal across various industries, and reaffirming their market viability in a rapidly changing economic landscape.

10 Best Rigid PVC Applications in 2023

Related Posts

-

Understanding the Impact of Injection Molding Pellets on Sustainable Manufacturing Practices

-

Top 10 Plastic Raw Materials Used in the Manufacturing Industry Today

-

What is Plastic Raw Material Types and Their Applications

-

10 Essential Tips for Mastering Injection Moulding Techniques

-

2025 Trends in Mold Injection Molding: Innovations and Market Insights

-

Understanding PVC Flexible Materials: The Versatile Choice for Your Next Project