2026 Best PVC Raw Material Types for Your Projects?

When selecting materials for your projects, understanding the types of PVC raw material available is crucial. PVC, or polyvinyl chloride, is widely used in industries for its durability and versatility. However, not all PVC raw materials are created equal.

Different applications require specific types of PVC. For instance, rigid PVC is often chosen for pipes and fittings due to its strength. On the other hand, flexible PVC is ideal for electrical cables and flooring. Each type presents unique characteristics that can impact performance and longevity. Choosing the right form of PVC raw material can be daunting, and even small inconsistencies can lead to significant project complications.

Reflecting on your project’s needs is important. What will the material be used for? How long does it need to last? A misstep in selecting the correct PVC raw material may result in issues down the line. This guide will explore the best types of PVC raw materials, focusing on their features and common applications to help you make informed decisions.

Types of PVC Raw Materials: An Overview of Available Options

PVC raw materials come in various types, each with unique properties suited for different applications. The most common types include rigid PVC, flexible PVC, and CPVC (Chlorinated Polyvinyl Chloride). According to market analysis from the PVC industry, rigid PVC is popular for construction and plumbing due to its strength and durability. Flexible PVC, conversely, is often used in electrical insulation and flooring because of its adaptability.

Recent reports indicate the global demand for PVC is projected to reach 50 million tons by 2025. This growth highlights the increasing reliance on PVC materials in numerous sectors. However, with rising environmental concerns, the industry faces challenges. The production of certain types of PVC can result in harmful emissions. The push for sustainable alternatives is gaining traction. This shift may reshape the types of PVC raw materials available in the near future.

When selecting PVC materials, it is crucial to consider their applications. Not all PVC is created equal. Some options may not perform well under extreme conditions. For instance, flexible PVC can degrade faster than rigid variants when exposed to harsh UV light. Understanding the limitations of each type is essential for optimizing project outcomes. Mixing different types may also yield unpredictable results, leading to performance issues down the line.

2026 Best PVC Raw Material Types for Your Projects

| PVC Type | Applications | Properties | Advantages |

|---|---|---|---|

| Flexible PVC | Electrical cables, flooring, medical devices | High flexibility, good electrical insulation | Durable, cost-effective, easy to process |

| Rigid PVC | Pipes, fittings, window profiles | High strength, low impact resistance | Excellent weather resistance, good mechanical properties |

| PVC Foam | Signage, construction boards | Lightweight, good thermal insulation | Easy to handle, versatile applications |

| Chlorinated PVC (CPVC) | Hot water pipes, industrial applications | Higher temperature resistance | Extended service life, corrosion resistance |

| Polyvinylidene Fluoride (PVDF) | Chemical processing, semiconductor fabrication | Exceptional chemical resistance | Long-lasting performance, high purity |

Properties of PVC Raw Materials: Key Characteristics to Consider

PVC raw materials are popular due to their versatility. They are used in many projects, from pipes to flooring. Understanding their key properties is essential. One major characteristic is durability. PVC is resistant to weathering and chemical corrosion. This makes it suited for outdoor applications.

Another important property is its flexibility. Some PVC types can be easily molded. This allows for various designs and applications. However, too much flexibility can lead to vulnerabilities. For example, overly flexible PVC may not hold up under stress.

Additionally, consider the material's insulation properties. PVC is a good electrical insulator. This feature is crucial for electrical applications. Still, always test the insulation effectiveness before use.

Another critical aspect is the environmental impact. While PVC is recyclable, its production raises concerns. We must reflect on these aspects when selecting the right PVC for any project.

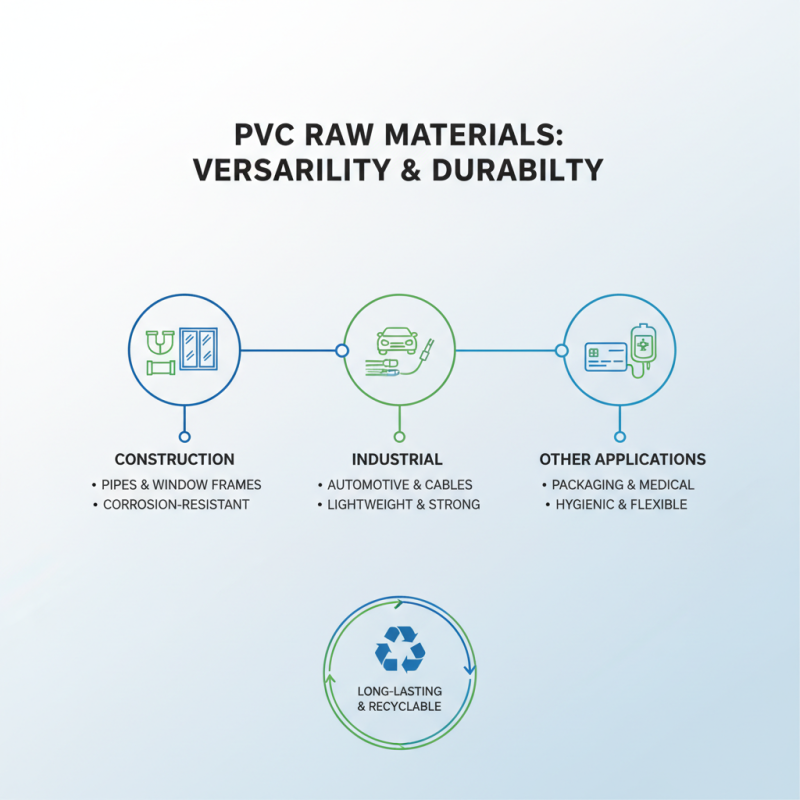

Applications of PVC Raw Materials in Various Industries

PVC raw materials play a crucial role in various industries. Their versatility makes them suitable for numerous applications. In construction, PVC is commonly used for pipes and window frames. Its resistance to corrosion ensures durability in challenging environments. Many builders appreciate its strength and lightweight properties.

In the automotive sector, PVC is used for interior trims and dashboards. Its flexibility allows for intricate designs, enhancing the overall aesthetic. However, some might question its environmental impact. Recycling PVC poses challenges that need addressing. Balancing performance and sustainability remains key for manufacturers.

Healthcare also benefits from PVC, particularly in medical devices. Its sterilization capability is vital for safety in medical environments. Yet, the perception of PVC's safety in human exposure warrants further investigation. Continuous dialogue about improvement and innovation is essential in all these areas.

Comparing the Cost-Effectiveness of Different PVC Types

When choosing PVC raw materials, cost-effectiveness plays a crucial role. Different PVC types, such as rigid and flexible, have unique cost structures. Rigid PVC is typically less expensive, coming in at an average of $1.20 per pound. In contrast, flexible PVC ranges around $2.00 per pound. The choice greatly impacts your project budget.

Data from industry reports indicate that while rigid PVC can lower initial costs, flexible PVC offers better durability. Projects requiring flexibility may incur higher costs initially, but these materials reduce repair expenses over time. A study from the Plastics Industry Association noted that using flexible PVC reduced maintenance costs by up to 30% in specific applications.

However, not every project benefits from these averages. Sometimes, the application conditions can render one type more effective than another. For instance, if the project environment is aggressive, rigid PVC might perform poorly. Thus, analyzing specific project needs is important. The need for reflection on material selection is vital. Balancing upfront costs and long-term benefits is essential for sustainable projects.

2026 Best PVC Raw Material Types Cost-Effectiveness Comparison

Sustainability Practices in PVC Raw Material Production and Use

PVC raw materials have often faced criticism regarding their environmental impact. However, improvements are emerging. The production of PVC is evolving. For instance, many companies report significant advancements in reducing carbon footprints. A recent industry report highlighted that up to 30% of PVC production now utilizes recycled materials. This shift not only conserves resources but reduces waste effectively.

Sustainability practices in PVC production must be a priority. Proper waste management strategies are essential. Many facilities are increasing energy efficiency by up to 20%. This has direct implications for reducing greenhouse gas emissions. However, the journey is not without challenges. Current recycling rates in the PVC industry stand at approximately 10%. This highlights a significant area needing attention. Increased investment in recycling technologies is crucial for future progress.

End-of-life PVC management options continue to vary. Some materials face barriers to recycling due to contamination. This complicates efforts to close the loop on recycled content. Innovations, like chemical recycling, hold promise but require further exploration. Continuous effort to enhance sustainability practices in PVC production will determine its future impact on our planet.

Related Posts

-

Understanding PVC Flexible Materials: The Versatile Choice for Your Next Project

-

Exploring the Versatility of Polyvinyl Chloride Material in Modern Applications

-

10 Essential Tips for Selecting Rigid PVC Pipe: Maximize Durability and Performance Based on Industry Standards

-

What is PVC Additives and How Do They Enhance Plastic Performance

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

10 Essential Tips for Mastering Injection Moulding Techniques