Best Plastic Injection Process Techniques and Tips?

In the world of manufacturing, mastering the plastic injection process is crucial. Industry expert John Smith once stated, "Understanding the nuances of injection molding can set a business apart." His insight highlights the importance of technique and precision in achieving quality results.

Plastic injection process involves several stages, each demanding attention to detail. Temperature control, material choice, and machine calibration play vital roles. Even minor errors can lead to significant defects. For instance, variations in temperature can affect material flow, leading to uneven surfaces or structural weaknesses.

Achieving perfection in the plastic injection process is an ongoing challenge. Companies often confront hurdles in consistency and efficiency. It’s essential to learn from mistakes and refine techniques continually. Embracing feedback and seeking improvements can transform potential failures into valuable lessons. This journey requires dedication and resilience, as there’s always room to improve.

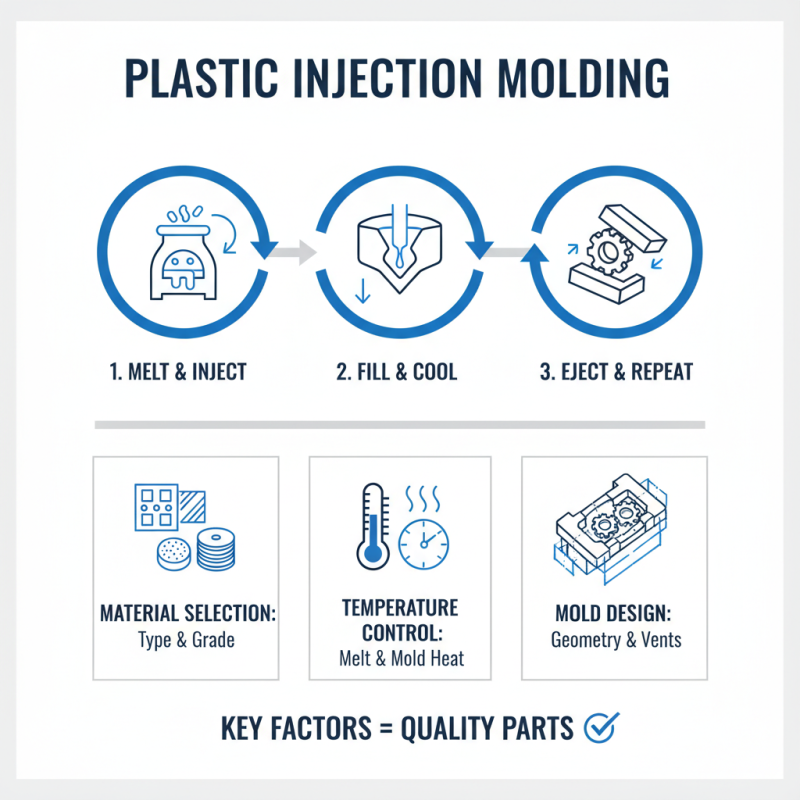

Understanding the Basics of Plastic Injection Molding Techniques

Understanding plastic injection molding techniques is crucial for achieving high-quality parts. This method involves injecting molten plastic into a mold, where it cools and solidifies. The process is efficient, allowing for mass production of complex shapes. However, various factors can impact the outcome. Material selection, temperature control, and mold design play significant roles in the final product quality.

Tips for a successful injection molding process include ensuring uniform material temperature. An inconsistent temperature can cause defects. Also, pay attention to the mold design. A well-designed mold minimizes stress and improves precision. Additionally, constant monitoring of cycle times can enhance efficiency. Adjusting settings based on observations will lead to better results.

Even with the best techniques, imperfections can arise. It is essential to review the produced parts regularly. Identifying flaws can lead to improvements in the process. Make adjustments and refine techniques as needed. Each production run offers learning opportunities. Embrace the challenges that come with this method to ensure continuous improvement.

Key Factors Influencing the Plastic Injection Process Efficiency

Efficiency in the plastic injection process depends on various key factors. Understanding these factors can enhance production quality and reduce costs. The cooling time, for instance, plays a significant role. If parts cool too quickly, it could lead to warping. Conversely, if they take too long, the cycle time increases unnecessarily.

Material selection is another crucial element. Different plastics have unique properties, affecting injection speed and pressure. It’s essential to choose materials that align with your design requirements. Inadequate material can result in defects. Always test prototypes before full-scale production.

**Tips:** Optimize your machine settings. Adjusting temperature and pressure may yield better results. Monitor the injection speed; it impacts the flow and finish. Regular maintenance of machines can prevent unexpected breakdowns. Don't overlook the importance of training operators. A skilled team can make better decisions on the spot. These small adjustments can lead to significant improvements.

Key Factors Influencing Plastic Injection Process Efficiency

Advanced Techniques for Optimizing Plastic Injection Quality

Optimizing plastic injection quality is crucial for manufacturers. A recent industry report indicated that improving injection techniques can reduce defects by up to 30%. Precision in temperature control is vital. Ideally, maintaining the melt temperature between 180°C and 220°C ensures optimal flow and minimizes stresses in the material. Even slight deviations can lead to visible imperfections.

Another advanced technique is the use of mold flow analysis software. It helps predict how molten plastic will fill the mold. Incorrect filling patterns may result in weak spots. By analyzing these patterns beforehand, manufacturers can adjust parameters. This proactive approach can lead to a 20% decrease in production time. However, reliance on software alone can sometimes overlook real-world variables, like moisture levels in resin.

Regular maintenance of injection molding machines is often underestimated. Worn-out components can affect the injection pressure and lead to inconsistencies. Scheduling routine check-ups every 6 months can aid in preventing unexpected breakdowns. Failure to adhere to maintenance schedules can lead to expensive repairs and downtime. Continuous reflection on these practices improves overall manufacturing quality.

Common Challenges and Solutions in Plastic Injection Molding

Plastic injection molding is widely used in manufacturing, yet it isn’t without its challenges. Issues like warping, air traps, and poor surface finish often arise. According to a recent industry report, around 35% of designers face difficulties with dimensional stability. This can lead to increased production costs and delays in project timelines. Understanding the root causes of these problems is key to finding effective solutions.

For instance, warping can be mitigated by optimizing cooling time and temperature settings. Many manufacturers overlook the importance of these parameters. A slight variation in cooling can result in significant defects. Additionally, air traps can be troublesome when mold designs don’t allow for proper venting. Research suggests that 20% of defects are linked to inadequate ventilation in the mold. It’s crucial to regularly review design specifications and make necessary adjustments.

Employees or operators can also be a source of inconsistency. A study found that 40% of material waste is attributed to improper handling. Regular training can address this issue. Moreover, there is often hesitation to adopt new technologies, like simulation software that can predict molding issues. Yet, companies that embrace these innovations tend to see a 15% reduction in defects. Overcoming these challenges requires proactive measures and ongoing education.

Best Practices for Maintenance and Troubleshooting in Injection Molding

Injection molding is a complex process that requires careful attention to detail. Maintenance of injection molding machines is crucial. Regular checks can prevent breakdowns and improve efficiency. It's vital to keep components clean. Clogged nozzles lead to inconsistent product quality.

Troubleshooting is necessary when issues arise. Look for signs of wear on parts. If defects appear, inspect the mold. A minor misalignment can cause major problems. Regularly calibrate machines to ensure accuracy.

Tips: Always document maintenance schedules. This helps in tracking and identifying recurring issues. Train operators on basic troubleshooting techniques. They should know the signs of potential problems. Encourage them to report any irregularities immediately. Early detection can save time and resources.

Best Plastic Injection Process Techniques and Tips

| Technique | Description | Best Practices | Common Issues |

|---|---|---|---|

| Heat Balance | Ensures consistent temperature throughout the mold. | Regularly check and maintain heating elements. | Uneven part cooling, leading to warping. |

| Cycle Time Optimization | Reduces production time without compromising quality. | Analyze and streamline each phase of production. | Increased cycle times can affect productivity. |

| Mold Maintenance | Routine cleaning and inspection to prolong mold life. | Establish a clear maintenance schedule. | Mold damage leading to production delays. |

| Material Selection | Choosing appropriate materials for durability and performance. | Consider end-use and processing characteristics. | Material incompatibility causing defects. |

| Injection Pressure Control | Maintains part quality and reduces flash. | Adjust pressure settings based on part design. | Too high pressure can cause defects in the product. |

Related Posts

-

Top 10 Benefits of Injection Moulding for Efficient Manufacturing

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

Why Understanding the Plastic Moulding Process is Essential for Manufacturers

-

Top 10 Benefits of the Plastic Moulding Process You Need to Know