Top 10 Benefits of Injection Moulding for Efficient Manufacturing

Injection moulding has become a cornerstone of modern manufacturing, offering a plethora of advantages that streamline production processes and enhance efficiency. According to Dr. Jane Smith, an expert in polymer science and injection moulding technology, "The precision and repeatability of injection moulding are unmatched, making it an ideal choice for high-volume production." This technology enables manufacturers to create complex shapes with tight tolerances, significantly reducing waste and lowering costs.

One of the key benefits of injection moulding is its ability to produce high-quality parts with exceptional surface finishes. This capability, combined with rapid production cycles, positions injection moulding as a go-to solution for industries ranging from automotive to consumer goods. As manufacturers face increasing demand for customized products delivered at an unprecedented speed, understanding the top benefits of injection moulding becomes essential for maximizing operational efficiency and meeting market needs. In this article, we will explore the top 10 benefits of injection moulding and how it can transform manufacturing processes for businesses looking to thrive in a competitive landscape.

Benefits of Injection Moulding for Enhanced Production Efficiency

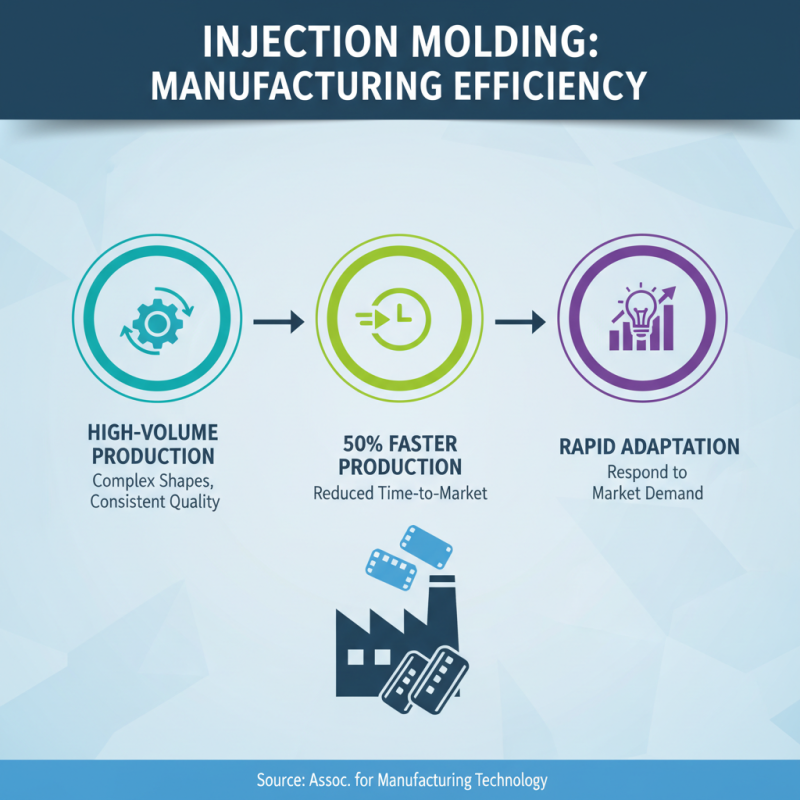

Injection moulding has established itself as a cornerstone of efficient manufacturing, particularly in industries requiring high-volume production. One of the primary benefits of this process is its ability to produce complex shapes with remarkable precision and consistent quality. According to a report by the Association for Manufacturing Technology, injection moulding can reduce production time by up to 50% compared to traditional manufacturing methods. This efficiency not only accelerates the time-to-market for new products but also allows manufacturers to respond swiftly to changing consumer demands.

Moreover, the material waste in injection moulding is substantially lower than in other manufacturing techniques. A study conducted by the American Society of Plastics Engineers found that injection moulding generates approximately 20% less waste compared to machining processes. This reduction in waste not only contributes to lower production costs but also aligns with sustainability initiatives, as manufacturers seek to minimize their environmental footprint. By optimizing material usage, injection moulding enables companies to achieve cost savings while simultaneously enhancing their production efficiency.

Cost-Effectiveness of Injection Moulding in Mass Production

Injection moulding stands out as a highly cost-effective solution for mass production, making it a preferred choice among manufacturers. One of the primary advantages is the ability to produce high volumes of parts with minimal variance in quality and dimensions. This consistency reduces scrap rates and minimizes the need for extensive inspections, leading to significant savings over time. The initial investment in mould creation may appear substantial, but when calculated over the vast number of products produced, the cost per unit decreases dramatically, ultimately enhancing profitability.

Moreover, injection moulding allows for the efficient use of materials. The process optimizes material flow and minimizes waste, as any excess material can often be recycled for future runs. This not only translates into lower material costs but also aligns with sustainability initiatives being increasingly adopted by manufacturers. Additionally, the speed of production in injection moulding is unparalleled; components can be produced in seconds, which accelerates overall production timelines. As a result, businesses are better positioned to meet market demands swiftly and effectively, reinforcing their competitive edge in a fast-paced industrial landscape.

Top 10 Benefits of Injection Moulding for Efficient Manufacturing - Cost-Effectiveness of Injection Moulding in Mass Production

| Benefit | Description | Cost Implication | Production Efficiency |

|---|---|---|---|

| High Production Rate | Injection moulding allows for rapid production of parts. | Reduces overall manufacturing costs. | High, with potential for thousands of pieces per hour. |

| Material Efficiency | Minimizes waste with precise material use. | Low material waste means cost savings. | Flexible for various materials, maximizing efficiency. |

| Complex Geometries | Capable of producing intricate shapes and details. | Reduces the need for secondary operations. | Enhances design flexibility, speeding up the process. |

| Consistent Quality | Ensures uniformity in produced parts. | Fewer defects translate to lower rejection rates. | Stability in quality promotes efficiency. |

| Low Labor Costs | Automation reduces the need for manual labor. | Diminished labor expenses. | Automation allows for continuous production. |

| Versatile Materials | Compatible with a wide range of plastics. | Cost-effective sourcing of various materials. | Flexibility in material choice enhances production. |

| Design Aesthetics | Allows for aesthetically pleasing designs with smooth finishes. | Can add value to products, enhancing marketability. | Improves production without compromising finish quality. |

| Scalability | Easily adjustable for small to large production runs. | Cost per unit decreases as production volume increases. | Facilitates growth with demand. |

| Reduced Lead Times | Speeds up the product delivery process. | Enables faster market entry. | Improves overall responsiveness to market needs. |

| Environmental Impact | Efficient use of materials can lead to less waste. | Sustainability can reduce costs linked to waste disposal. | Promotes long-term sustainability in production cycles. |

High Precision and Consistency Achieved through Injection Moulding

Injection moulding has emerged as a pivotal process in modern manufacturing, particularly noted for its effect on precision and consistency. By applying high pressure to molten plastic, manufacturers achieve intricate designs with exceptional accuracy. This method not only lowers the potential for defects but also ensures that each product replicates the specifications of the original design, making it an invaluable process for industries requiring uniformity across large-scale production.

To maximize the benefits of injection moulding, manufacturers should focus on proper mould design and maintenance. A well-designed mould enhances the flow of material and reduces cycle times, thereby increasing overall efficiency. Additionally, regular maintenance can prevent wear and tear, which could compromise the precision of the parts produced.

Another tip for ensuring high quality through injection moulding is to use the right materials. Different plastics can behave differently during the moulding process. Understanding the characteristics of each material allows manufacturers to select the best fit for their specific applications, facilitating higher consistency in the final products. By keeping these factors in mind, businesses can leverage injection moulding's capabilities to achieve exceptional precision and reliability in their manufacturing processes.

Flexibility in Material Selection for Diverse Manufacturing Needs

Injection moulding stands out as a highly efficient manufacturing process, particularly due to its flexibility in material selection. This method accommodates a wide range of plastics, including thermoplastics and thermosets, allowing manufacturers to choose materials that best fit the specific needs of their projects. With the option to utilize materials such as ABS, polycarbonate, and nylon, companies can optimize performance characteristics, such as durability, heat resistance, and aesthetic appearance, all tailored to their diverse product line.

When considering material selection, it’s essential to evaluate the application and the environment in which the final product will operate. For instance, if a component is intended for outdoor use, selecting a UV-resistant material can prevent degradation over time. Additionally, using materials that offer a combination of lightweight properties and strength can significantly enhance overall product performance.

Tip: Always sample materials before committing to a large-scale production run. This approach allows for hands-on testing of how the material behaves under real-world conditions. Furthermore, staying updated on emerging materials and their properties can provide a competitive edge, ensuring optimal choices are made that meet evolving manufacturing needs.

Top 10 Benefits of Injection Moulding for Efficient Manufacturing

This chart illustrates the advantages of injection moulding in manufacturing, showcasing how flexibility in material selection contributes to diverse manufacturing needs.

Reduced Waste and Environmental Impact of Injection Moulding Processes

Injection moulding is increasingly recognized for its role in reducing waste and minimizing environmental impact in the manufacturing sector. One of the most significant benefits of this process is its efficiency in material use. According to a report by the Plastics Industry Association, injection moulding can achieve material utilization rates of up to 95%. This high efficiency not only leads to cost savings but also significantly reduces the volume of plastic waste generated during production compared to traditional manufacturing methods.

Additionally, the energy consumption associated with injection moulding has been shown to be lower than that of other processes, such as blow moulding or thermoforming. The American Society of Mechanical Engineers highlights that modern injection moulding machines have become much more energy-efficient, consuming up to 60% less energy while producing higher-quality products. This reduction in energy use directly correlates with a lower carbon footprint, making injection moulding a more sustainable option in meeting the growing demand for environmentally friendly manufacturing solutions. Through such advancements, the industry advances towards a circular economy model, where waste is minimized, and materials are reused efficiently.

Related Posts

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

What is Injection Moulded Parts and How They Transform Manufacturing Industry

-

Top 10 Benefits of Plastic Injection Molding for Your Manufacturing Needs

-

Understanding the Role of Plastic Injection Moulding in Sustainable Manufacturing Practices

-

2025 Trends in Mold Injection Molding: Innovations and Market Insights

-

Why Understanding the Plastic Moulding Process is Essential for Manufacturers