2026 Top Trends in Mould Injection Machines for Manufacturers Seeking Efficiency?

In the evolving landscape of manufacturing, efficiency stands paramount. The mould injection machine plays a crucial role in this. According to a recent report by MarketsandMarkets, the global market for injection molding machines is projected to reach $16.5 billion by 2026. This growth reflects an increasing demand for advanced technology in production processes.

Manufacturers are seeking ways to enhance productivity while minimizing waste. The latest trends in mould injection machines focus on automation and precision. These machines now integrate smart technology, ensuring optimal performance. However, as manufacturers embrace this change, challenges remain. Many firms grapple with the steep learning curve associated with new technologies.

Cost remains a significant consideration. Transitioning to advanced mould injection machines requires substantial investment. However, the long-term benefits often outweigh initial expenses. The industry must adapt continuously or risk falling behind. Embracing these trends can lead to greater efficiency, but careful planning is essential for success.

Emerging Technologies in Mould Injection Machines for 2026

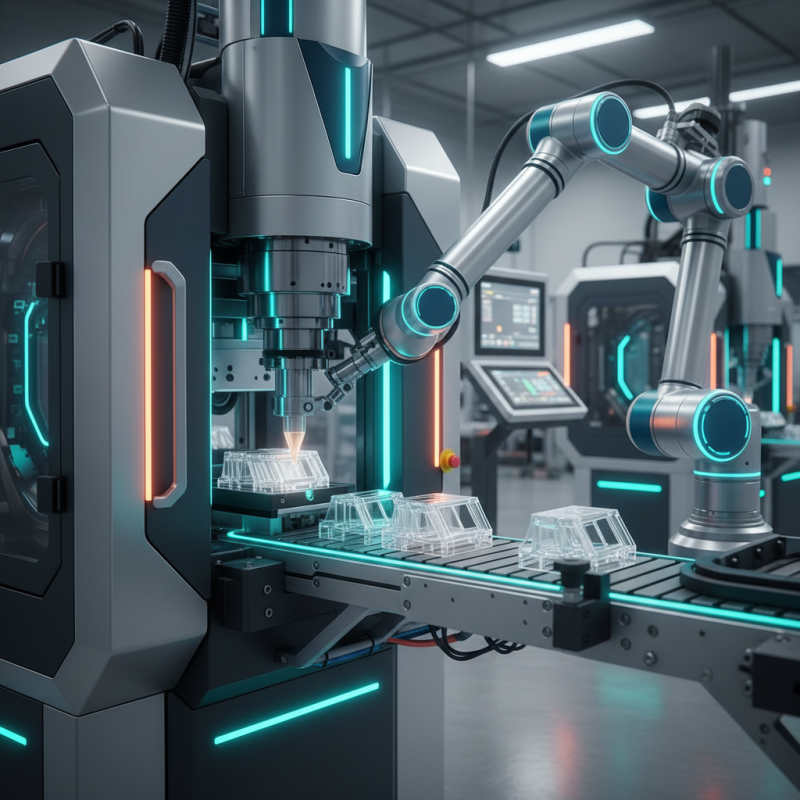

As we look toward 2026, mould injection machines are becoming increasingly sophisticated. Emerging technologies will reshape how manufacturers approach efficiency. One significant trend is the rise of automation in these machines. Lines equipped with smart robotics will reduce human intervention, enhancing precision and speed. However, challenges remain in integrating these systems seamlessly.

Additionally, the adoption of artificial intelligence can optimize production processes. AI can analyze data in real time, predicting maintenance needs before breakdowns occur. This could lead to significant cost savings. Yet, not all manufacturers may be prepared for this shift, leaving some behind as they struggle with legacy systems.

Sustainability is another crucial theme. Companies are exploring eco-friendly materials and methods. This transition can be complex and resource-intensive. Manufacturers might face difficulties in retraining staff or adjusting supply chains. The pursuit of efficiency through innovation must also consider these hurdles, requesting reflective solutions to move forward effectively.

Integration of Artificial Intelligence for Enhanced Efficiency

The integration of artificial intelligence in mould injection machines is transforming manufacturing efficiency. AI can analyze vast amounts of data in real-time. This leads to precision in production that manual methods cannot easily replicate. Manufacturers are increasingly seeking smarter solutions.

AI-driven systems can predict failures before they occur. This proactive approach reduces downtime significantly. However, small errors can still arise in AI models, causing unexpected issues. These challenges highlight the need for continuous monitoring and adjustments. Not every factory has embraced this shift. Some remain rooted in traditional practices, fearing the unknown.

Implementing AI requires investment and training. It’s not merely about purchasing new machines; it’s about changing a mindset. The transition can be slow, and resistance is common among seasoned workers. They may struggle with new technology. Yet, the potential rewards are substantial, as AI optimizes every step from design to production. Balancing innovation with human expertise is essential for a successful transformation.

Sustainability Trends in Mould Injection Processes

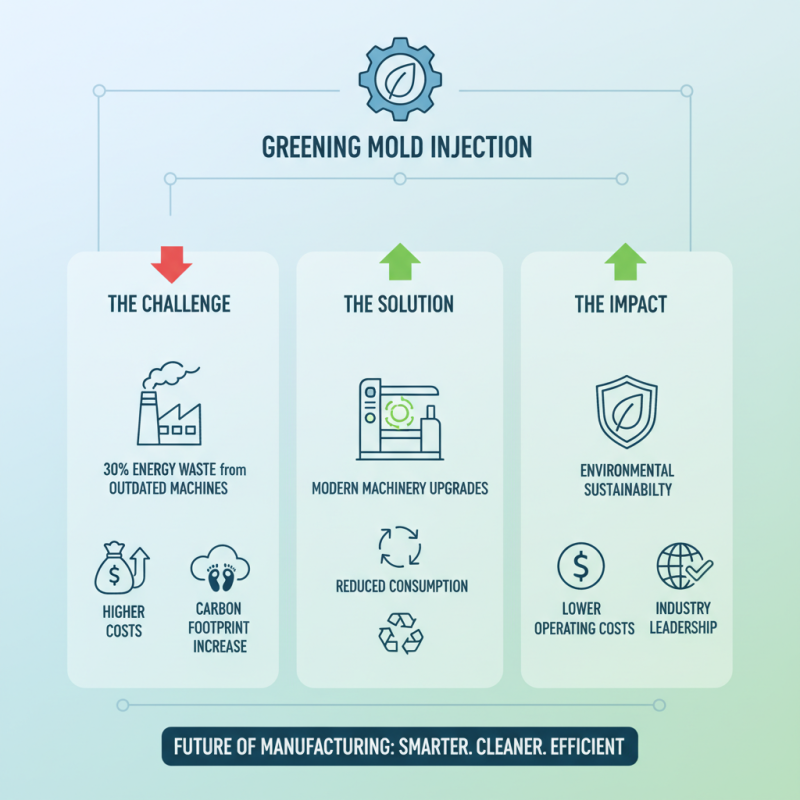

Sustainability in mould injection processes is becoming crucial for manufacturers. Recent studies show that around 30% of energy consumption in this sector comes from outdated machinery. This inefficiency leads to higher costs and increased carbon footprints. The industry must address these challenges head-on.

New trends focus on eco-friendly materials and reduced energy usage. For instance, companies are exploring biopolymers, which can lower dependency on fossil fuels. The use of biodegradable materials is projected to rise by 25% in the next five years. Automation and energy-efficient technologies can further enhance production efficiency while minimizing waste. However, not all firms are adopting these practices swiftly.

There’s a noticeable gap in sustainability knowledge among manufacturers. Research indicates that only 40% understand how to implement eco-friendly practices effectively. Training employees in these methods is essential. Relying on traditional practices can hinder progress. The industry's push towards sustainability should not be merely a trend; it needs to evolve into an operational standard.

Advancements in Materials Used for Injection Moulding

The injection moulding industry is evolving rapidly. Material advancements are at the forefront of this evolution. Manufacturers are increasingly exploring innovative materials that enhance product durability and reduce waste. New polymers are being developed that offer better strength-to-weight ratios. These materials can lead to more efficient production processes.

Sustainability is another critical factor. Many companies are now prioritizing eco-friendly materials. Biodegradable plastics are gaining traction. However, manufacturers face challenges. These materials may not always match the performance of traditional options. Finding the right balance is essential. Experimentation with various blends is common.

As manufacturers embrace these changes, they need to remain cautious. Not all advancements yield immediate benefits. Some new materials require adjustments in machinery and processes. A thorough evaluation is necessary before making any commitments. Investing in the wrong material could lead to costly mistakes. Adaptation is key, but it must be measured.

Automation and Robotics in Mould Injection Manufacturing

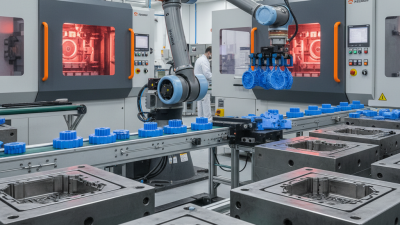

Automation and robotics are transforming mould injection manufacturing. As companies strive for efficiency, these technologies play a critical role. They reduce manual labor, increase precision, and enhance productivity. Modern mould injection machines can now operate with minimal human intervention. This shift can lead to significant cost savings for manufacturers.

However, challenges accompany this transition. Not all factories have the resources or expertise to implement automation systems. Workers may feel threatened by job displacement. Additionally, integrating new technologies can disrupt established workflows. Some manufacturers struggle to adapt to the fast-paced changes. Ensuring that employees receive proper training is vital for a smooth transition.

Investing in automation is essential for staying competitive. But it requires thoughtful planning and consideration. Understanding the specific needs of the production line is crucial. Balancing human inputs with robotic efficiency can create a productive environment. The goal is to enhance, not replace, the workforce. Companies must reflect on their processes to ensure they leverage automation effectively.

2026 Top Trends in Mould Injection Machines

Related Posts

-

10 Essential Tips for Mastering Large Injection Moulding Techniques

-

Understanding the Impact of Injection Molding Pellets on Sustainable Manufacturing Practices

-

2025 Top 5 Injection Molding Pellets for Enhanced Manufacturing Efficiency

-

Top 5 Benefits of Injection Tooling for Efficient Manufacturing Process

-

2025 How to Choose the Best PVC Moulding Machine for Your Business

-

What is Plastic Raw Material Types and Their Applications